Products

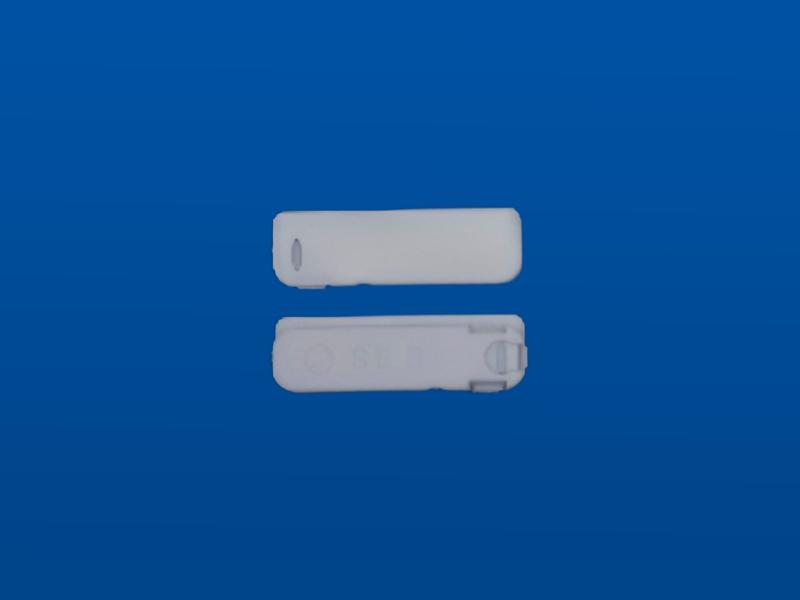

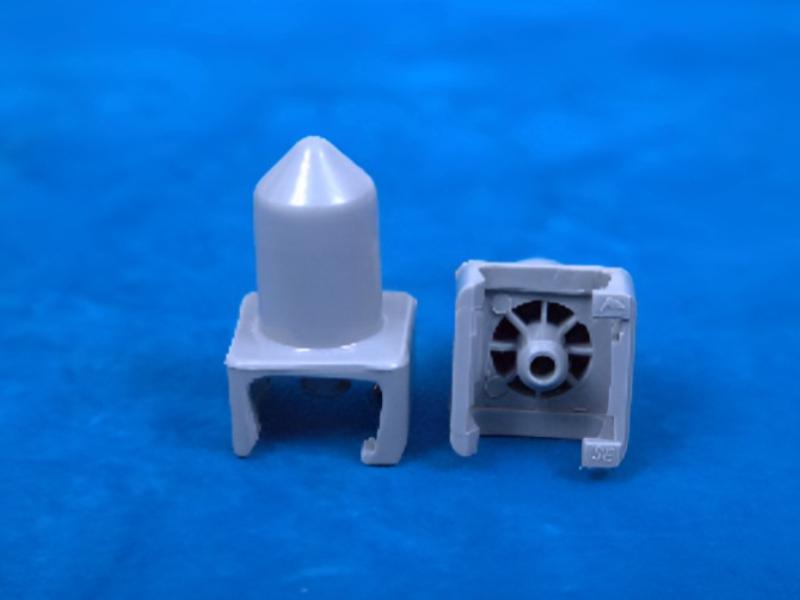

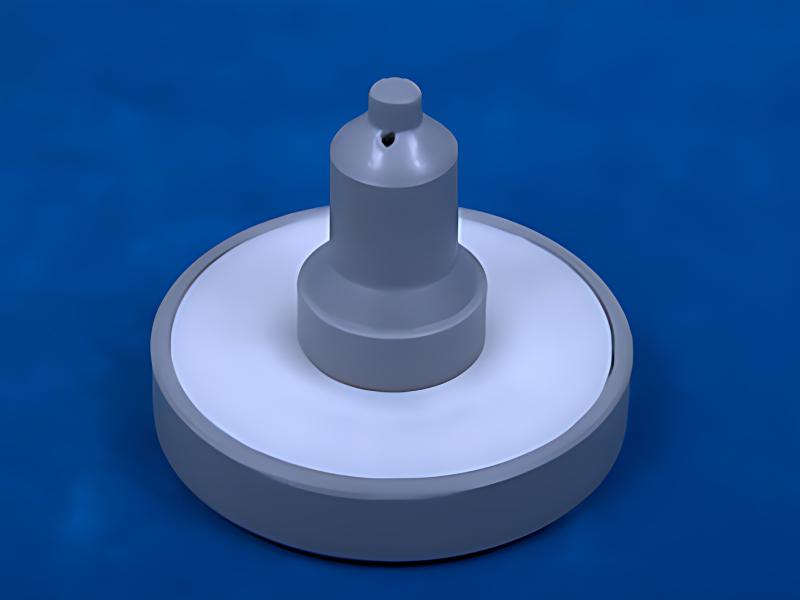

The Gripper Cap Grey 18 DUI for KTTM Autodoffer is engineered to provide secure coverage and protection for gripper assemblies in Autodoffer systems. Manufactured using high-quality industrial-grade materials, it ensures durability under continuous textile mill operations. The 18 DUI configuration offers precise compatibility with KTTM Autodoffer machines. Precision molding ensures accurate dimensions for proper fitment and alignment. Its robust construction helps protect internal gripper components from wear and operational stress. The grey finish supports easy identification during maintenance and replacement.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Gripper Cap Grey 18 DUI KTTM Autodoffer Spares

- Component Type Autodoffer Gripper Cap

- Color Grey

- Configuration 18 DUI

- Application KTTM LR Autodoffer Machines

- Function Protection & Stability of Gripper Assembly

- Material Industrial-Grade Polymer / Composite

Other Attributes

- Surface Finish Wear-Resistant

- OEM Compatibility KTTM Autodoffer Models

- Customization Material Type, Finish

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

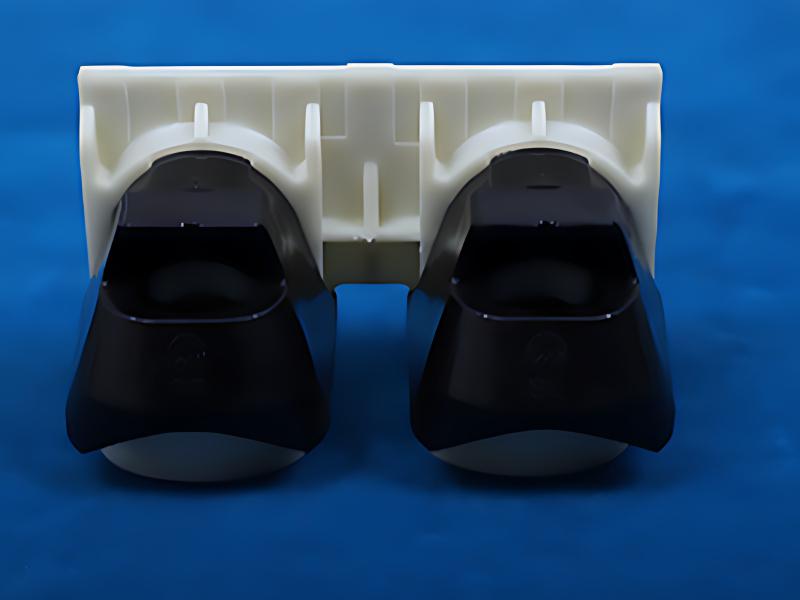

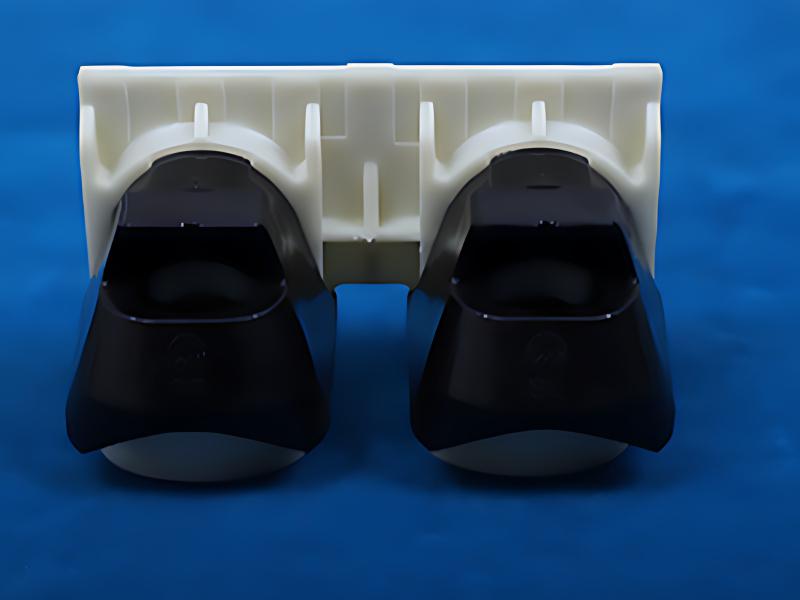

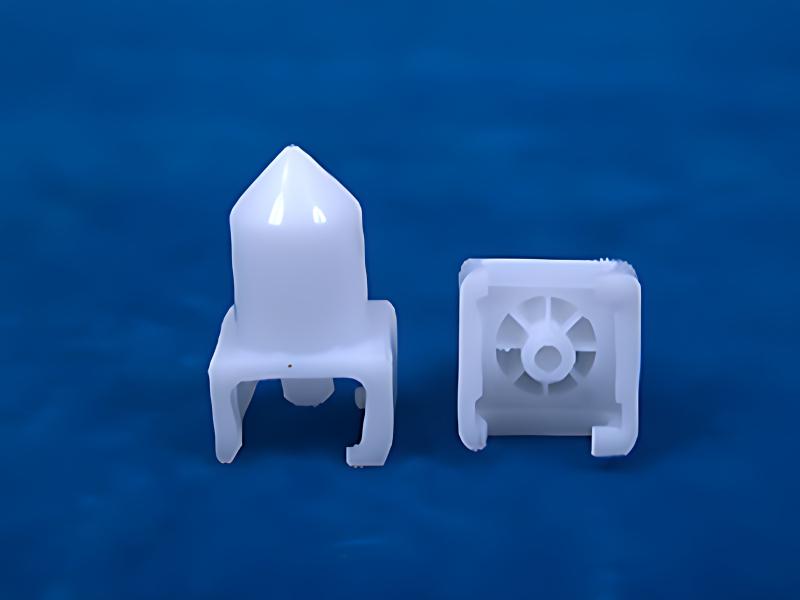

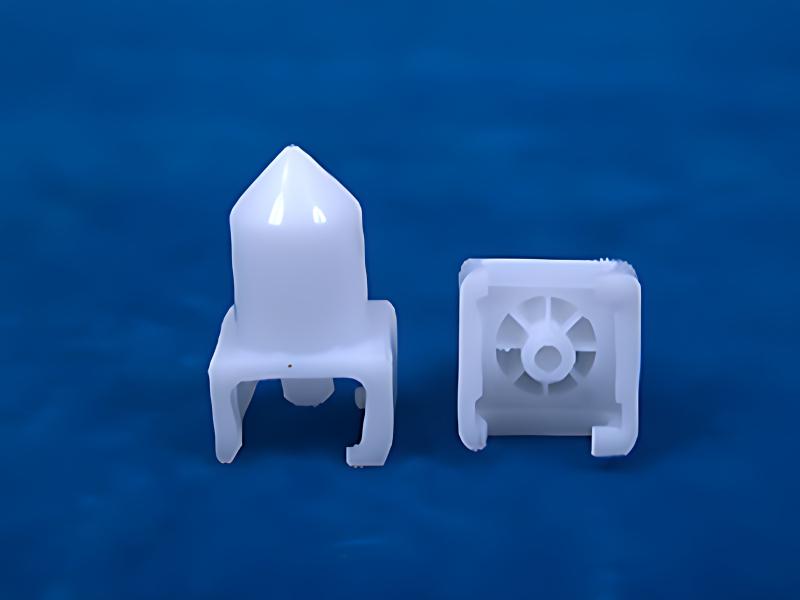

The Gripper Cap Black 20 DUI for KTTM Autodoffer is engineered to provide secure coverage and enhanced protection for gripper assemblies in Autodoffer systems. Manufactured using high-quality industrial-grade materials, it ensures durability under continuous textile mill operations. The 20 DUI configuration delivers precise compatibility with KTTM Autodoffer machines. Precision molding ensures accurate dimensions for proper fitment and alignment. Its robust construction helps safeguard internal gripper components from wear and mechanical stress.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Gripper Cap Black 20 DUI KTTM Autodoffer Component

- Component Type Autodoffer Gripper Cap

- Color Black

- Configuration 20 DUI

- Application KTTM LR Autodoffer Machines

- Function Protection & Stability of Gripper Assembly

- Material Industrial-Grade Polymer / Composite

Other Attributes

- Surface Finish Wear-Resistant

- OEM Compatibility KTTM Autodoffer Models

- Customization Material Type, Finish

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

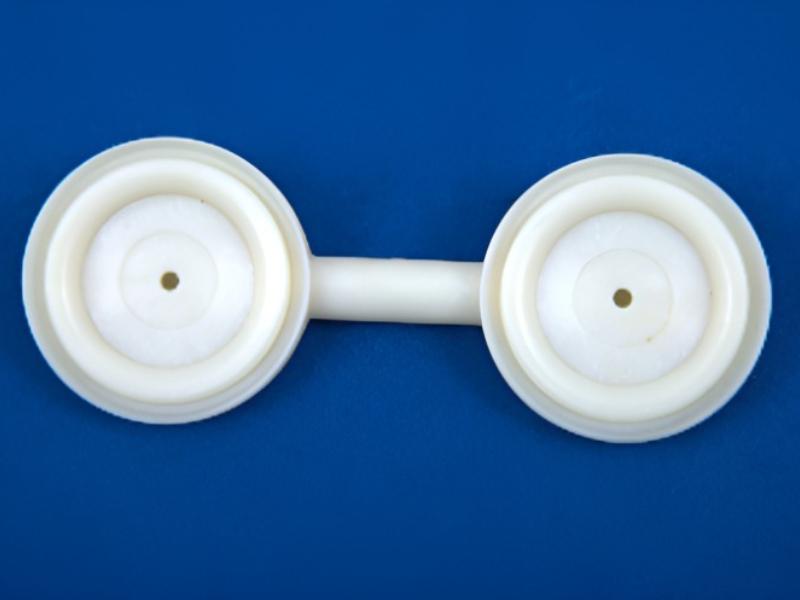

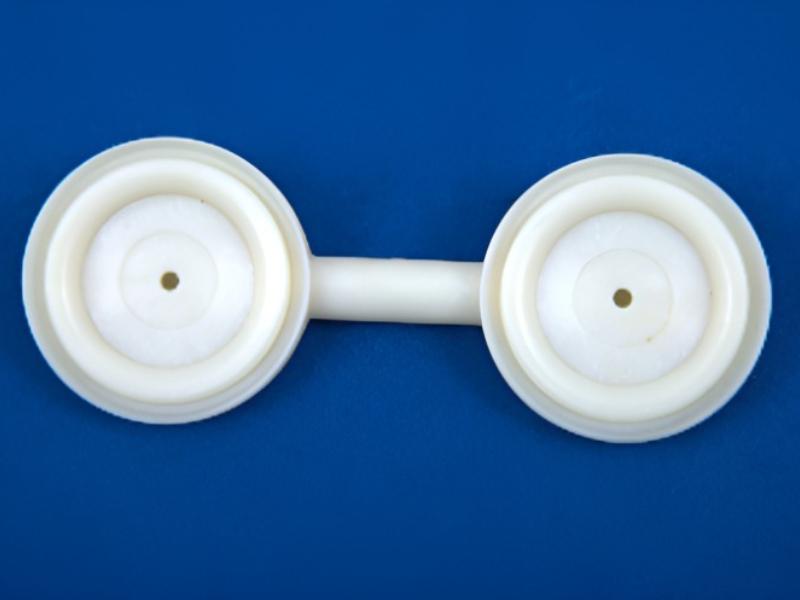

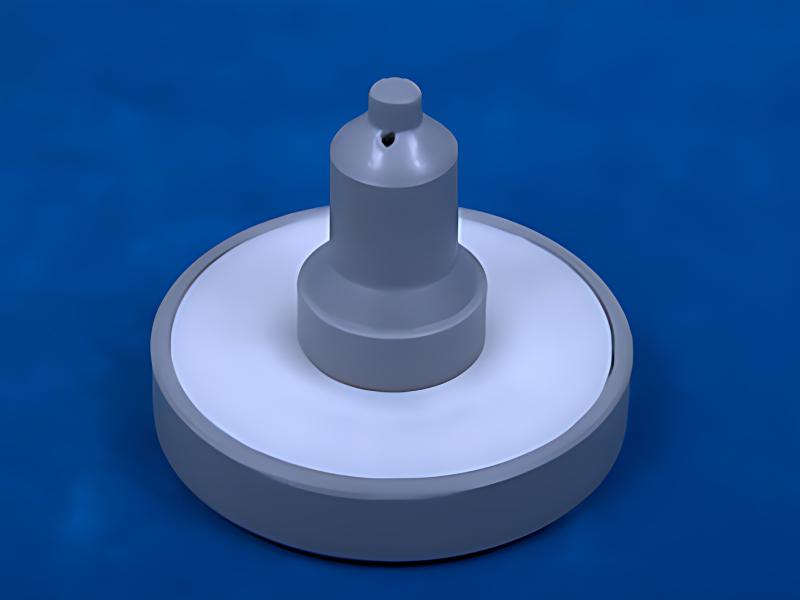

The Diaphragm for KTTM Autodoffer is engineered to deliver consistent flexibility and reliable performance within Autodoffer systems. Manufactured from high-quality industrial-grade materials, it ensures durability under continuous textile mill operation. Precision molding provides accurate dimensions for proper sealing and fitment. The diaphragm supports controlled pressure or pneumatic action essential for smooth doffing cycles. Its wear- and fatigue-resistant properties enhance long service life in demanding environments.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Diaphragm KTTM Autodoffer Spare Item

- Component Type Autodoffer Diaphragm

- Material Industrial-Grade Rubber / Elastomer

- Application KTTM LR Autodoffer Machines

- Function Pressure Control & Sealing

- Design Flexible Precision-Molded

Other Attributes

- Surface Finish Smooth, Wear-Resistant

- OEM Compatibility KTTM Autodoffer Models

- Customization Material Type, Thickness

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

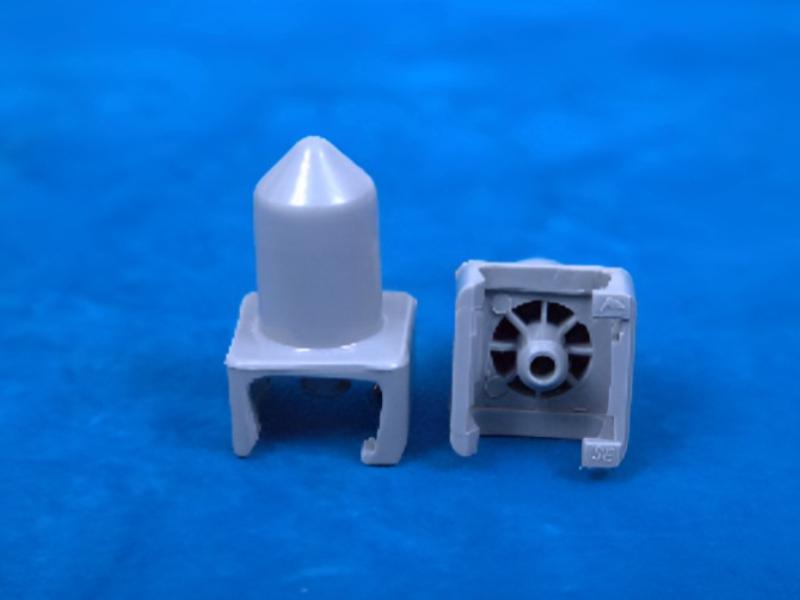

The Piston Without Spring for KTTM Autodoffer is engineered to provide precise linear motion within Autodoffer systems. Manufactured from high-strength industrial materials, it ensures durability under continuous textile mill operation. The spring-less design allows controlled movement when paired with external actuation mechanisms. Precision machining ensures accurate dimensions for smooth sliding and proper sealing. Its wear- and corrosion-resistant surface enhances long-term reliability. The component supports consistent Autodoffer performance during high-speed doffing cycles.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Piston Without Spring KTTM Autodoffer Part

- Component Type Autodoffer Piston

- Design Without Spring

- Material High-Strength Industrial Metal / Alloy

- Application KTTM LR Autodoffer Machines

- Function Linear Motion Control

Other Attributes

- Surface Finish Wear- and Corrosion-Resistant

- OEM Compatibility KTTM Autodoffer Models

- Customization Material Grade, Dimensions, Finish

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The Piston Spring for KTTM Autodoffer is engineered to deliver consistent elasticity and reliable return action within Autodoffer piston assemblies. Manufactured from high-quality spring-grade material, it ensures durability under continuous textile mill operation. Precision coiling provides uniform load distribution and stable performance. The spring supports smooth piston reset during high-speed doffing cycles. Its fatigue-resistant properties enhance long service life in demanding environments.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Piston Spring KTTM Autodoffer Spare

- Component Type Autodoffer Piston Spring

- Material Spring-Grade Steel / Alloy

- Application KTTM LR Autodoffer Machines

- Function Piston Return & Motion Control

- Design Precision-Coiled Spring

Other Attributes

- Surface Finish Wear- and Fatigue-Resistant

- OEM Compatibility KTTM Autodoffer Models

- Customization Spring Design, Material

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The Pallet Plate End Gripper for KTTM Autodoffer is engineered to provide reliable clamping and support for pallet plate ends during Autodoffer cycles. Manufactured using high-strength industrial materials, it ensures durability under continuous textile mill operations. Precision machining guarantees accurate dimensions for secure fitment and alignment with pallets. The gripper enhances smooth material handling and consistent doffing performance. Its wear- and corrosion-resistant surface ensures long-term reliability in demanding production environments.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Pallet Plate End Gripper KTTM Autodoffer

- Component Type Autodoffer Pallet Gripper

- Material High-Strength Industrial Metal / Alloy

- Application KTTM LR Autodoffer Machines

- Function Securing & Supporting Pallet Plate Ends

- Design Precision-Machined Gripper

Other Attributes

- Surface Finish Wear- and Corrosion-Resistant

- OEM Compatibility KTTM Autodoffer Models

- Customization Material Grade, Finish

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The Tube for Pallet in KTTM Autodoffer is engineered to provide structural support and smooth movement for pallet assemblies in Autodoffer systems. Manufactured from high-strength industrial materials, it ensures durability under continuous textile mill operations. Precision machining guarantees accurate dimensions for proper fitment and alignment with pallets. The tube helps maintain stability and consistent operation during high-speed doffing cycles. Its wear- and corrosion-resistant surface enhances long-term reliability. Easy installation and replacement reduce maintenance time and machine downtime.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Tube for Pallet KTTM Autodoffer Spare Part

- Component Type Autodoffer Pallet Tube

- Material High-Strength Industrial Metal / Alloy

- Application KTTM LR Autodoffer Machines

- Function Pallet Support & Smooth Motion

- Design Precision-Machined Tube

Other Attributes

- Surface Finish Wear- and Corrosion-Resistant

- OEM Compatibility KTTM Autodoffer Models

- Customization Material Grade, Dimensions, Finish

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The O Ring for KTTM Autodoffer is engineered to provide reliable sealing and prevent leakage in Autodoffer systems. Manufactured from high-quality elastomeric or polymer materials, it ensures durability under continuous textile mill operation. Precision molding provides accurate dimensions for proper fitment and optimal sealing. The O Ring helps maintain smooth mechanical movement of Autodoffer assemblies. Its wear- and corrosion-resistant properties enhance long-term performance in demanding production environments.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name O Ring KTTM Autodoffer Component

- Component Type Autodoffer Sealing Ring

- Material Industrial-Grade Elastomer / Polymer

- Application KTTM LR Autodoffer Machines

- Function Sealing & Leak Prevention

- Design Precision-Molded O Ring

Other Attributes

- Surface Finish Wear- and Corrosion-Resistant

- OEM Compatibility KTTM Autodoffer Models

- Customization Material Type, Size, Hardness

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The Gripper Assembly 18 DUI for KTTM Autodoffer is engineered to deliver precise fiber gripping and consistent performance during Autodoffer operations. Manufactured from high-strength industrial materials, it ensures durability under continuous textile mill operation. The 18 DUI configuration provides accurate compatibility with KTTM Autodoffer machines. Precision machining guarantees proper alignment and smooth movement within the assembly. Its wear- and corrosion-resistant surface enhances reliability in demanding production environments.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Gripper Assembly 18 DUI KTTM Autodoffer

- Component Type Autodoffer Gripper Assembly

- Configuration 18 DUI

- Material High-Strength Industrial Metal / Alloy

- Application KTTM LR Autodoffer Machines

- Function Fiber Gripping & Doffing

Other Attributes

- Surface Finish Wear- and Corrosion-Resistant

- OEM Compatibility KTTM Autodoffer Models

- Customization Material Grade, Dimensions, Surface Finish

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The Gripper Assembly 20 DUI for KTTM Autodoffer is engineered to deliver accurate fiber gripping and reliable performance during Autodoffer operations. Manufactured from high-strength industrial materials, it ensures durability under continuous textile mill operation. The 20 DUI configuration offers precise compatibility with KTTM Autodoffer machines. Precision machining guarantees smooth movement and proper alignment within the gripper mechanism. Its wear- and corrosion-resistant surface enhances reliability in demanding production environments.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Gripper Assembly 20 DUI KTTM Autodoffer Spares

- Component Type Autodoffer Gripper Assembly

- Configuration 20 DUI

- Material High-Strength Industrial Metal / Alloy

- Application KTTM LR Autodoffer Machines

- Function Fiber Gripping & Doffing

Other Attributes

- Surface Finish Wear- and Corrosion-Resistant

- OEM Compatibility KTTM Autodoffer Models

- Customization Material Grade, Dimensions, Surface Finish

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The Intermediate Peg 18 DUI for KTTM Autodoffer is engineered to ensure precise alignment and controlled movement within Autodoffer mechanisms. Manufactured from high-strength industrial materials, it provides durability and long service life under continuous textile mill operations. Precision machining ensures accurate dimensions for secure fitment and consistent performance. The peg plays a critical role in maintaining correct spacing and positioning of Autodoffer assemblies. Its wear- and corrosion-resistant surface enhances reliability in demanding production environments.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Intermediate Peg 18 DUI KTTM Autodoffer

- Component Type Autodoffer Intermediate Peg

- Configuration 18 DUI

- Material High-Strength Industrial Metal / Alloy

- Application KTTM LR Autodoffer Machines

- Function Positioning & Alignment

Other Attributes

- Surface Finish Wear- and Corrosion-Resistant

- OEM Compatibility KTTM Autodoffer Models

- Customization Material Grade, Dimensions, Finish

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The Intermediate Peg 18 DUI for Autodoffer is manufactured to ensure precise alignment and controlled movement within Autodoffer mechanisms. Made from high-strength industrial-grade materials, it offers excellent durability under continuous textile mill operation. Precision machining ensures consistent dimensions and reliable fitment. The peg plays a vital role in maintaining correct spacing between Autodoffer components. Its wear- and corrosion-resistant surface enhances operational reliability in demanding environments. Easy installation and removal help reduce machine downtime during maintenance.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Intermediate Peg 18 DUI Autodoffer Spare

- Component Type Autodoffer Intermediate Peg

- Configuration 18 DUI

- Material High-Strength Industrial Metal / Alloy

- Application Autodoffer Spinning Machines

- Function Positioning & Alignment

Other Attributes

- Surface Finish Wear- and Corrosion-Resistant

- OEM Compatibility Autodoffer Machine Models

- Customization Material Grade, Dimensions, Finish

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The Bottom Peg Trey Peg 18.5 DUI for KTTM Autodoffer is manufactured to provide precise positioning and mechanical stability within Autodoffer assemblies. Made from high-strength industrial-grade materials, it ensures long service life in continuous textile production environments. Precision machining delivers accurate dimensions for secure and vibration-free fitment. The 18.5 DUI configuration ensures correct compatibility with KTTM Autodoffer systems. Its wear- and corrosion-resistant surface enhances reliability during high-speed doffing cycles.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Bottom Peg Trey Peg 18.5 DUI KTTM Autodoffer

- Component Type Autodoffer Bottom Peg / Trey Peg

- Configuration 18.5 DUI

- Material High-Strength Industrial Metal / Alloy

- Application KTTM LR Autodoffer Machines

- Function Bottom Positioning & Alignment

Other Attributes

- Surface Finish Wear- and Corrosion-Resistant

- OEM Compatibility KTTM Autodoffer Models

- Customization Material Grade, Dimensions, Finish

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The Bottom Peg Tray Peg 20 DUI for KTTM Autodoffer is manufactured to ensure precise positioning and mechanical stability within Autodoffer assemblies. Constructed from high-strength industrial-grade materials, it delivers reliable performance in continuous textile production environments. Precision machining ensures accurate dimensions for secure and vibration-free fitment. The 20 DUI configuration ensures correct compatibility with KTTM Autodoffer systems. Its wear- and corrosion-resistant surface enhances durability during high-speed doffing cycles.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Bottom Peg Tray Peg 20 DUI KTTM Autodoffer

- Component Type Autodoffer Bottom Peg / Tray Peg

- Configuration 20 DUI

- Material High-Strength Industrial Metal / Alloy

- Application KTTM LR Autodoffer Machines

- Function Bottom Positioning & Alignment

Other Attributes

- Surface Finish Wear- and Corrosion-Resistant

- OEM Compatibility KTTM Autodoffer Models

- Customization Material Grade, Dimensions, Finish

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The Spindle Brake for KTTM Autodoffer is engineered to provide reliable and controlled braking during Autodoffer operations. Manufactured from high-strength industrial-grade materials, it ensures long service life under continuous textile mill conditions. Precision machining guarantees accurate fitment and consistent braking performance. The brake plays a critical role in safely stopping spindle rotation during the doffing cycle. Its wear-resistant construction enhances durability and reduces maintenance frequency.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Spindle Brake KTTM Autodoffer Spare Part

- Component Type Autodoffer Spindle Brake

- Application KTTM LR Autodoffer Machines

- Function Controlled Spindle Braking

- Material High-Strength Industrial Metal / Composite

- Surface Finish Wear-Resistant

Other Attributes

- OEM Compatibility KTTM Autodoffer Models

- Customization Material, Surface Treatment

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The 38 T Compact Gear is designed for industrial and mechanical power transmission applications. It provides smooth torque transfer between connected machine components. Manufactured with precision for accurate tooth alignment and consistent operational performance. Durable material ensures long-term reliability under industrial conditions. Suitable for rotary, transmission, and drive systems. Compact design allows easy integration into diverse machinery assemblies. Ideal for industries requiring dependable, efficient, and precise mechanical motion control.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Teeth Count 38 Nos

- Module 2 mm

- Pitch Diameter 76 mm

- Outer Diameter 80 mm

- Bore Diameter 18 mm

- Face Width 12 mm

Other Attributes

- Hub Diameter 28 mm

- Hub Length 15 mm

- Weight 0.85 kg

- Maximum RPM 4500 rpm

- Operating Temperature -20°C to 150°C

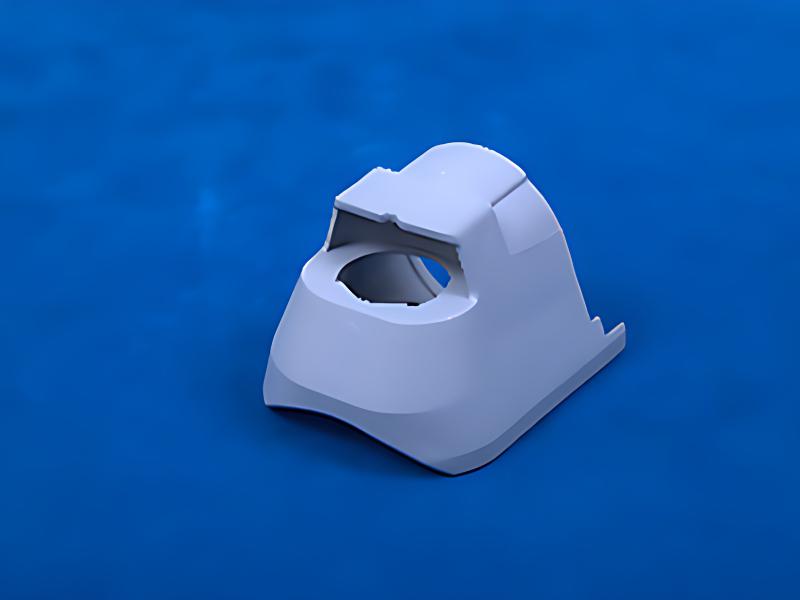

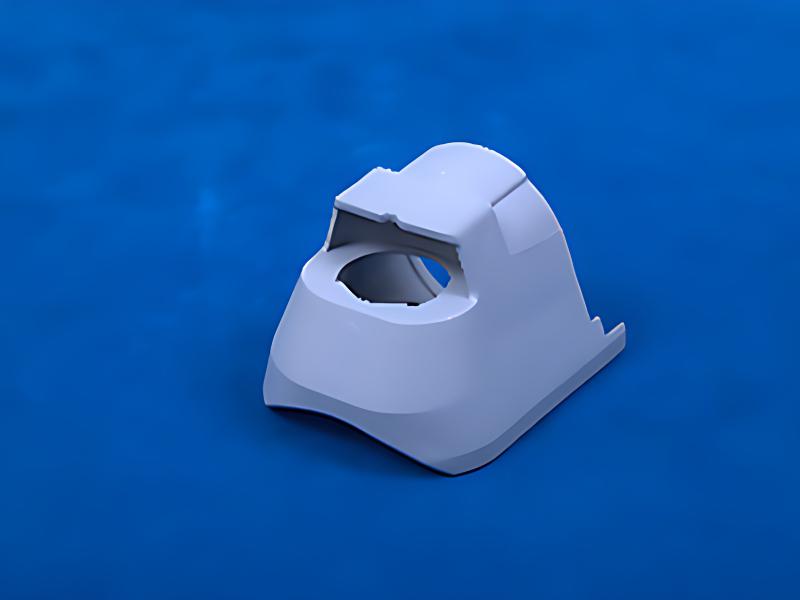

The Top Cradle Delivery Box is specially designed for KTTM Autodoffer systems in textile machinery. It supports organized handling and smooth delivery of components during automated operations. Manufactured with durable materials for long-term industrial performance. Precision design ensures proper fit and alignment within the autodoffer assembly. Compact structure allows easy integration into existing machine setups. Resistant to operational wear and frequent usage. Ideal for textile automation systems requiring reliable and efficient delivery support.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Length 220 mm

- Width 160 mm

- Height 140 mm

- Wall Thickness 3 mm

- Weight 1.25 kg

Other Attributes

- Mounting Hole Diameter 6 mm (4 Nos)

- Slot Width 12 mm

- Slot Length 40 mm

- Operating Temperature -10°C to 80°C

- Load Capacity 8 kg

The White Lattice Apron 39.5 By 17 is designed for protective use in autodoffer textile machinery. Its lattice structure offers coverage while maintaining airflow and visibility. Manufactured with durable material for long-term industrial performance. Precise dimensions ensure proper fit within autodoffer assemblies. Lightweight design allows easy installation and handling. Resistant to wear under continuous machine operation. Ideal for textile environments requiring both protection and operational clarity.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Length 39.5 in

- Width 17 in

- Thickness 1.2 mm

- Mesh Size 8 mm × 8 mm

- Weight 0.85 kg

Other Attributes

- Tensile Strength 32 MPa

- Operating Temperature -20°C to 80°C

- Edge Reinforcement Width 20 mm

- Color White

- UV Resistance Up to 800 hours