Products

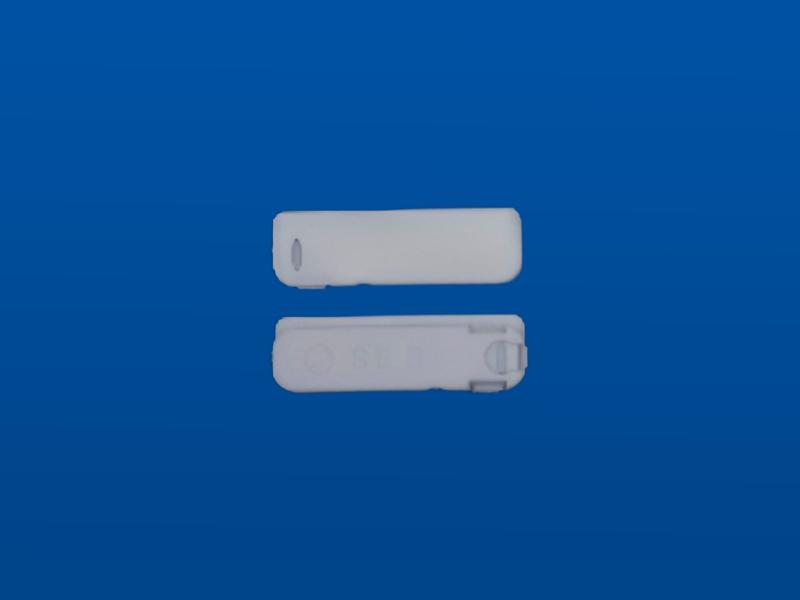

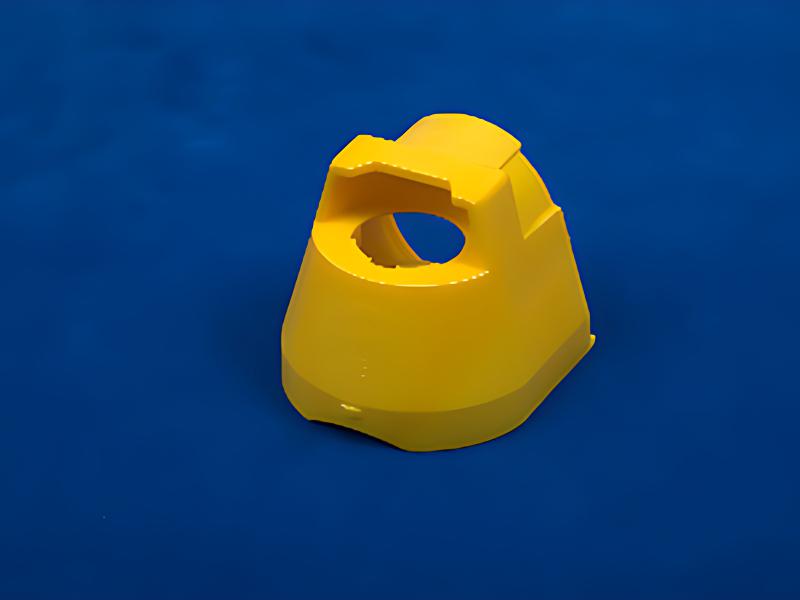

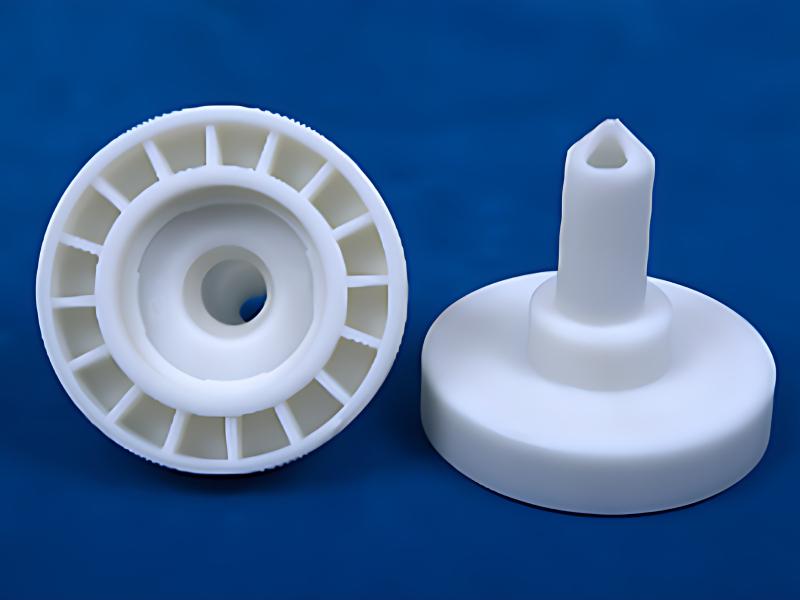

The Gripper Cap Old Type LR Autodoffer Spares is engineered to ensure secure fiber gripping and consistent operation in spinning machinery. Constructed from high-strength materials, it provides long-term durability and reliable performance under continuous use. The old-type design ensures compatibility with legacy LR Autodoffer models. Precision engineering guarantees accurate fitment, smooth operation, and minimal wear on connected components. Its corrosion- and wear-resistant surface enhances longevity even in demanding textile production environments.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Gripper Cap Old Type LR Autodoffer Spares

- Component Type Spinning Machine Gripper Cap

- Material High-Strength Industrial Metal / Alloy

- Application LR Autodoffer Spinning Machines

- Function Fiber Gripping & Handling

- Design Old Type

Other Attributes

- Surface Finish Wear- and Corrosion-Resistant

- OEM Compatibility LR Autodoffer Machine Models

- Customization Material, Size Options

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

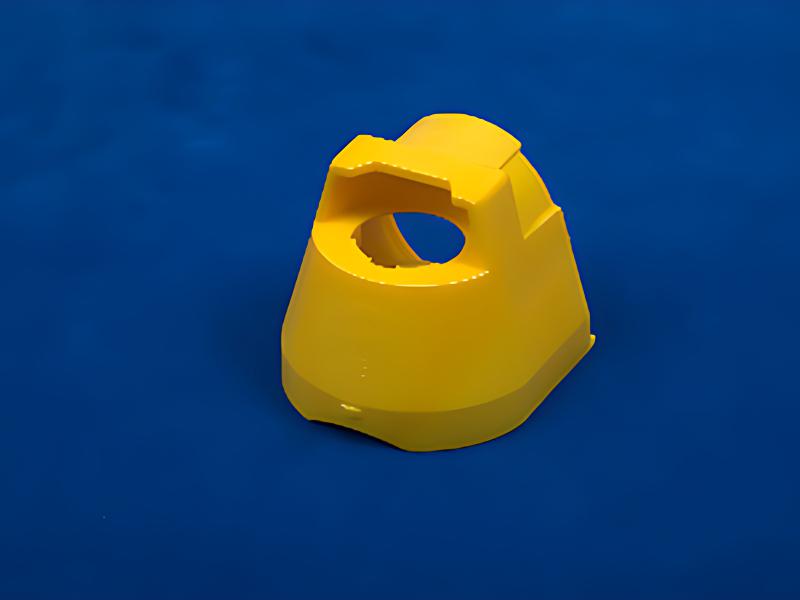

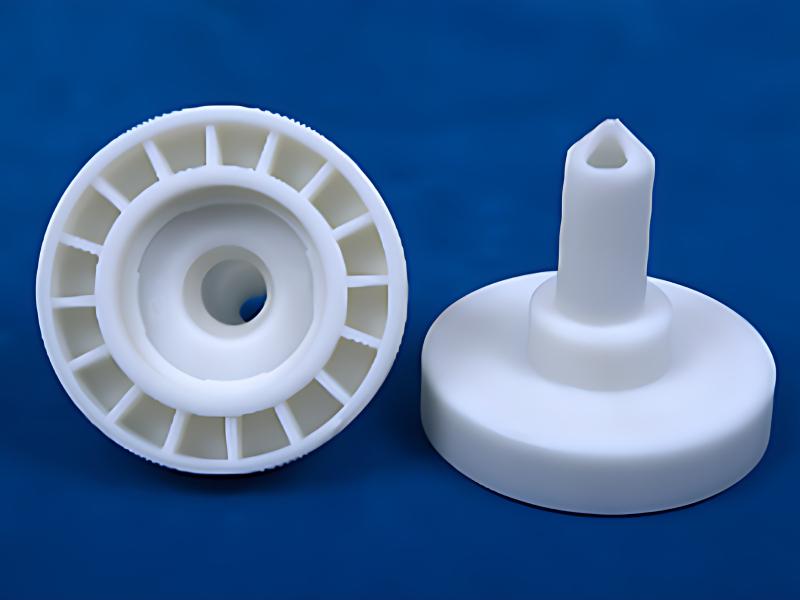

The Gripper Cap New Type LR Autodoffer Component is engineered to provide secure fiber gripping and consistent performance in spinning machinery. Manufactured from high-strength industrial materials, it ensures long-term durability and reliable operation under continuous use. The new-type design offers improved functionality and compatibility with modern LR Autodoffer assemblies. Precision engineering guarantees accurate fitment, smooth operation, and minimal wear on connected components. Its wear- and corrosion-resistant surface ensures longevity even in demanding textile production environments.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Gripper Cap New Type LR Autodoffer Component

- Component Type Spinning Machine Gripper Cap

- Material High-Strength Industrial Metal / Alloy

- Application LR Autodoffer Spinning Machines

- Function Fiber Gripping & Handling

- Design New Type

Other Attributes

- Surface Finish Wear- and Corrosion-Resistant

- OEM Compatibility LR Autodoffer Machine Models

- Customization Material, Size Options

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

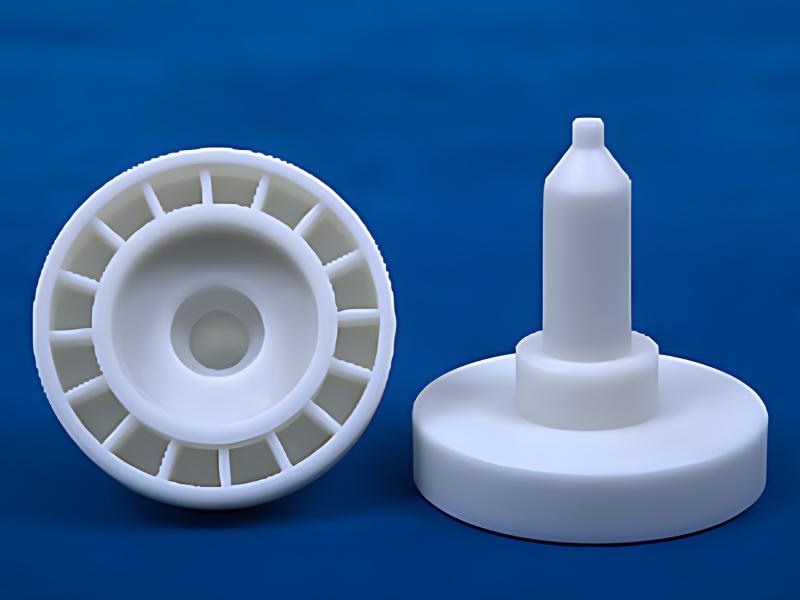

The Gripper Cap Round Type Autodoffer Spare is engineered to ensure reliable fiber gripping and consistent operation in spinning machinery. Manufactured from high-strength industrial materials, it provides long-term durability and dependable performance under continuous use. The round-type design allows uniform fiber handling and improved operational efficiency. Precision engineering guarantees accurate fitment and smooth motion within Autodoffer assemblies. Its wear- and corrosion-resistant surface ensures extended service life in demanding textile production environments.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Gripper Cap Round Type Autodoffer Spare

- Component Type Spinning Machine Gripper Cap

- Material High-Strength Industrial Metal / Alloy

- Design Round Type

- Application Autodoffer Spinning Machines

- Function Fiber Gripping & Handling

Other Attributes

- Surface Finish Wear- and Corrosion-Resistant

- OEM Compatibility Autodoffer Machine Models

- Customization Material, Diameter, and Design Options

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The Piston Without Spring for LR Autodoffer is engineered to provide reliable movement and fiber handling in Autodoffer assemblies. Constructed from high-strength industrial materials, it ensures long-term durability and stable performance under continuous operation. The design without a spring allows compatibility with specific machine configurations and modernized Autodoffer systems. Precision engineering guarantees accurate alignment and smooth motion within spinning machinery. Its wear- and corrosion-resistant surface enhances longevity in demanding textile production environments.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Piston Without Spring LR Autodoffer Part

- Component Type Spinning Machine Piston

- Material High-Strength Industrial Metal / Alloy

- Design Without Spring

- Application LR Autodoffer Spinning Machines

- Function Fiber Handling & Movement

Other Attributes

- Surface Finish Wear- and Corrosion-Resistant

- OEM Compatibility LR Autodoffer Machine Models

- Customization Material, Dimensions, and Surface Options

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The Diaphragm PU for LR Autodoffer is engineered to provide reliable suction and precise fiber handling in spinning machinery. Constructed from high-quality polyurethane material, it ensures durability, flexibility, and long-term performance under continuous use. The diaphragm maintains consistent airflow and pressure, supporting smooth operation of the Autodoffer assembly. Precision engineering guarantees accurate fitment and proper sealing within the machine. Its wear- and corrosion-resistant properties enhance longevity in demanding textile production environments. Easy installation and replacement minimize machine downtime and improve operational efficiency.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Diaphragm PU LR Autodoffer Spare Item

- Component Type Spinning Machine Diaphragm

- Material Polyurethane (PU)

- Application LR Autodoffer Spinning Machines

- Function Fiber Suction & Handling

- Design Flexible PU Diaphragm

Other Attributes

- Surface Finish Wear- and Corrosion-Resistant

- OEM Compatibility LR Autodoffer Machine Models

- Customization Material Grade, Dimensions, Thickness

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

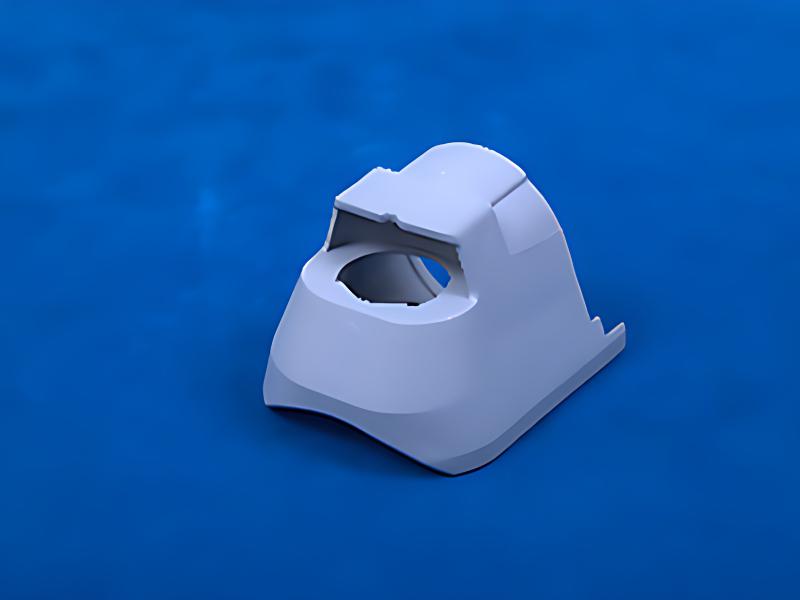

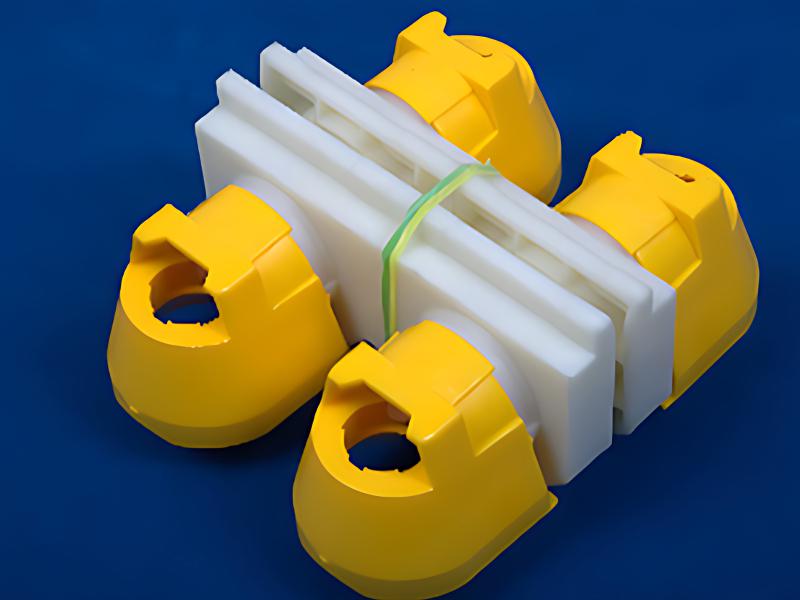

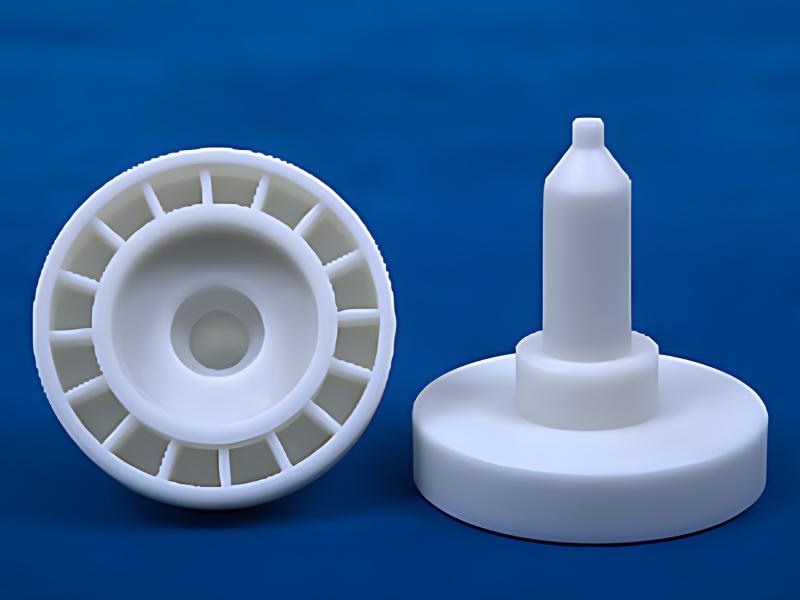

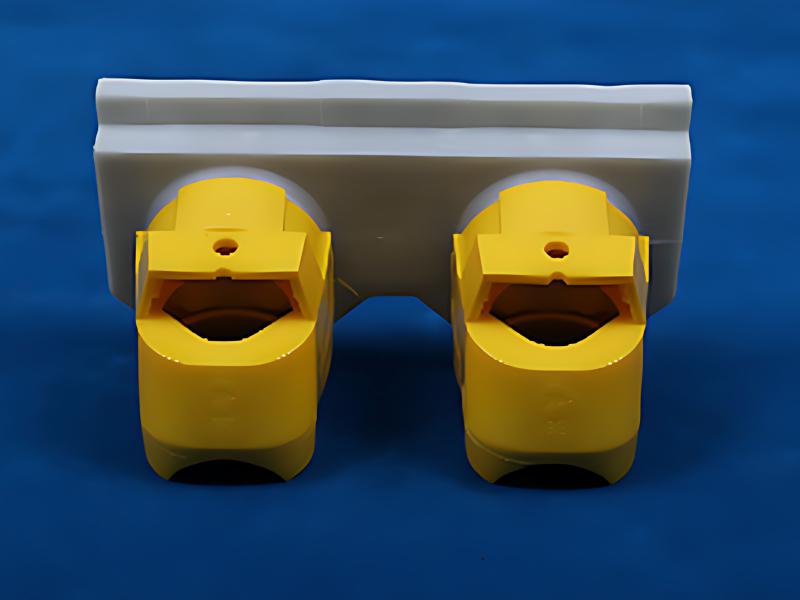

The Gripper Assembly Round Type for LR Autodoffer is engineered to provide reliable fiber gripping and consistent operation in spinning machinery. Constructed from high-strength industrial materials, it ensures long-term durability and dependable performance under continuous use. The round-type design allows uniform fiber handling and improved operational efficiency. Precision engineering guarantees accurate fitment and smooth motion within Autodoffer assemblies. Its wear- and corrosion-resistant surface enhances longevity even in demanding textile production environments.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Gripper Assembly Round Type LR Autodoffer

- Component Type Spinning Machine Gripper Assembly

- Material High-Strength Industrial Metal / Alloy

- Design Round Type

- Application LR Autodoffer Spinning Machines

- Function Fiber Gripping & Handling

Other Attributes

- Surface Finish Wear- and Corrosion-Resistant

- OEM Compatibility LR Autodoffer Machine Models

- Customization Material, Dimensions, and Surface Options

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The Piston With Spring Autodoffer Spare Part is designed to deliver controlled movement and consistent performance in textile spinning machinery. Manufactured using high-strength industrial materials, it ensures durability and long service life under continuous operation. The integrated spring mechanism provides smooth return action and stable operational control. Precision machining ensures accurate fitment within Autodoffer assemblies. The component supports reliable fiber handling and synchronized machine movement. Its wear- and corrosion-resistant surface enhances performance in demanding textile environments.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Piston With Spring Autodoffer Spare Par

- Component Type Autodoffer Piston Assembly

- Material High-Strength Industrial Metal / Allo

- Design With Integrated Spring

- Application Autodoffer Spinning Machines

- Function Motion Control & Fiber Handling

Other Attributes

- Surface Finish Wear- and Corrosion-Resistant

- OEM Compatibility Autodoffer Machine Models

- Customization Material, Spring Type, Dimensions

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The O Ring 10.00 x 3.00 Millimetre for Autodoffer is engineered to ensure effective sealing and consistent performance in textile spinning machinery. Manufactured from high-quality elastomer material, it provides flexibility and long service life. Precision molding ensures accurate dimensions for a tight and secure fit within Autodoffer assemblies. The O ring helps prevent air or fluid leakage, supporting smooth machine operation. Its wear- and abrasion-resistant properties enhance durability in continuous-use environments. Easy installation and replacement reduce maintenance time and machine downtime.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name O Ring 10.00 x 3.00 Millimetre Autodoffer

- Component Type Sealing O Ring

- Material Industrial Elastomer / Rubber

- Size 10.00 x 3.00 Millimetre

- Application Autodoffer Spinning Machines

- Function Leak-Proof Sealing

Other Attributes

- Shape Round

- OEM Compatibility Autodoffer Machine Models

- Customization Material Grade, Hardness Options

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The Intermediate Peg 18 DUI for LR Autodoffer is engineered to ensure precise positioning and smooth mechanical operation in Autodoffer systems. Manufactured from high-strength industrial materials, it provides durability and long service life under continuous machine operation. Precision machining ensures accurate dimensions for a secure and stable fit within the assembly. The peg supports synchronized movement and alignment of Autodoffer components. Its wear- and corrosion-resistant surface enhances performance in demanding textile production environments.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Intermediate Peg 18 DUI LR Autodoffe

- Component Type Autodoffer Positioning Peg

- Material High-Strength Industrial Metal / Alloy

- Configuration 18 DUI

- Application LR Autodoffer Spinning Machines

- Function Positioning & Alignment

Other Attributes

- Surface Finish Wear- and Corrosion-Resistant

- OEM Compatibility LR Autodoffer Machine Models

- Customization Material Grade, Surface Finish

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The Bottom Peg 18 DUI for Link Coner Autodoffer is engineered to ensure precise alignment and smooth mechanical movement within Autodoffer systems. Manufactured from high-strength industrial materials, it offers durability and long service life under continuous operation. Precision machining ensures accurate dimensions for secure fitment in Link Coner assemblies. The peg supports stable linkage and synchronized movement of Autodoffer components. Its wear- and corrosion-resistant surface enhances reliability in demanding textile production environments.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Bottom Peg 18 DUI Link Coner Autodoffer

- Component Type Autodoffer Positioning Peg

- Material High-Strength Industrial Metal / Alloy

- Configuration 18 DUI

- Application Link Coner Autodoffer Machines

- Function Positioning & Linkage Support

Other Attributes

- Surface Finish Wear- and Corrosion-Resistant

- OEM Compatibility Link Coner Autodoffer Models

- Customization Material Grade, Surface Finish

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The Bottom Peg 18 DUI Taper Tip for Autodoffer is engineered to ensure precise alignment and smooth mechanical interaction within Autodoffer systems. Manufactured from high-strength industrial materials, it offers durability and long service life under continuous machine operation. The taper tip design enables easy engagement and accurate positioning during Autodoffer cycles. Precision machining ensures consistent dimensions and secure fitment within the assembly. Its wear- and corrosion-resistant surface enhances reliability in demanding textile production environments.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Bottom Peg 18 DUI Taper Tip Autodoffer

- Component Type Autodoffer Positioning Peg

- Material High-Strength Industrial Metal / Alloy

- Configuration 18 DUI

- Design Taper Tip

- Application Autodoffer Spinning Machines

- Function Positioning & Engagement

Other Attributes

- Surface Finish Wear- and Corrosion-Resistant

- OEM Compatibility Autodoffer Machine Models

- Customization Material Grade, Surface Finish

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The Bottom Peg 18 DUI for Link Coner Bottom Mesh is engineered to ensure precise alignment and stable support within Autodoffer systems. Manufactured from high-strength industrial materials, it provides durability and long service life under continuous operation. Precision machining ensures accurate dimensions for secure fitment in Link Coner assemblies. The peg supports proper positioning of the bottom mesh, ensuring smooth Autodoffer functionality. Its wear- and corrosion-resistant surface enhances reliability in demanding textile production environments.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Bottom Peg 18 DUI Link Coner Bottom Mesh

- Component Type Autodoffer Positioning Peg

- Material High-Strength Industrial Metal / Alloy

- Configuration 18 DUI

- Application Link Coner Autodoffer Machines

- Function Bottom Mesh Positioning & Support

Other Attributes

- Surface Finish Wear- and Corrosion-Resistant

- OEM Compatibility Link Coner Autodoffer Models

- Customization Material Grade, Surface Finish

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

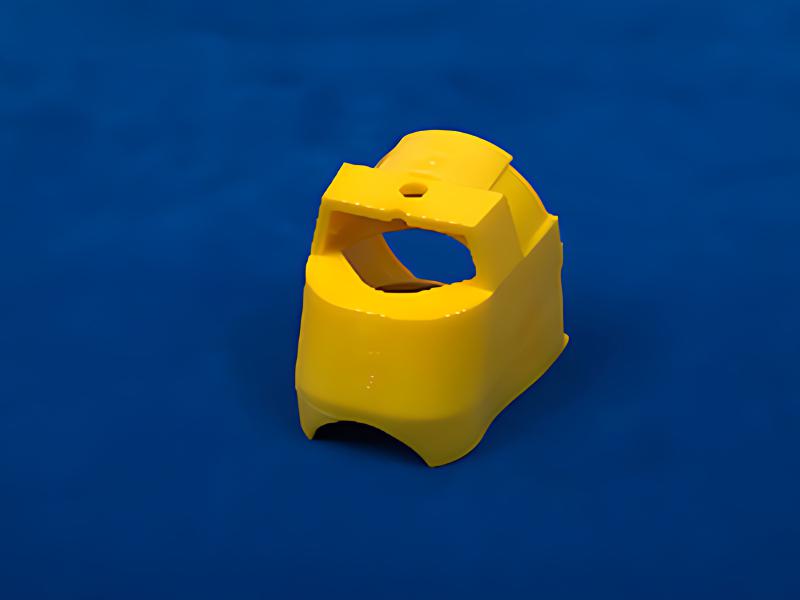

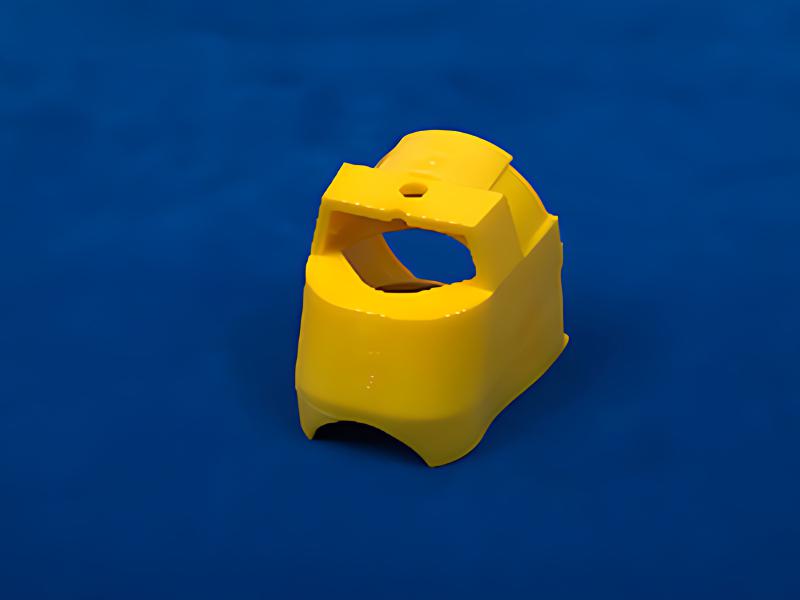

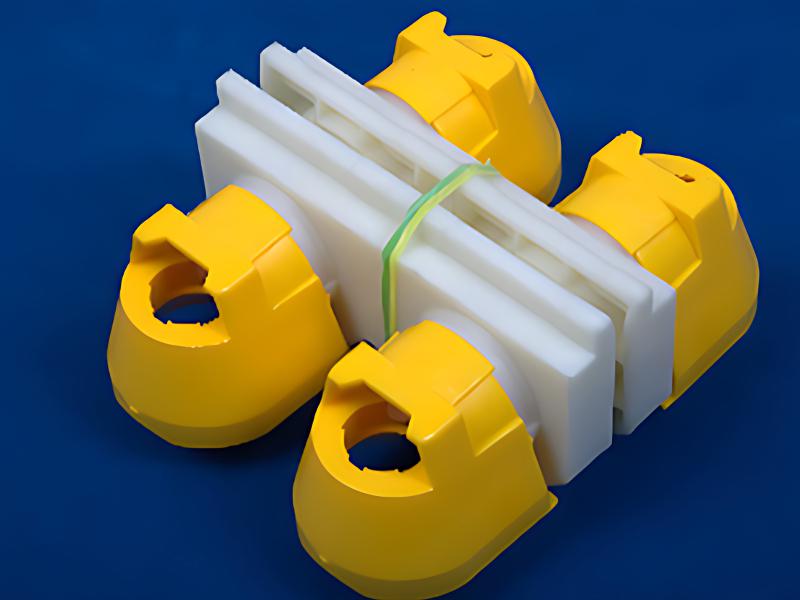

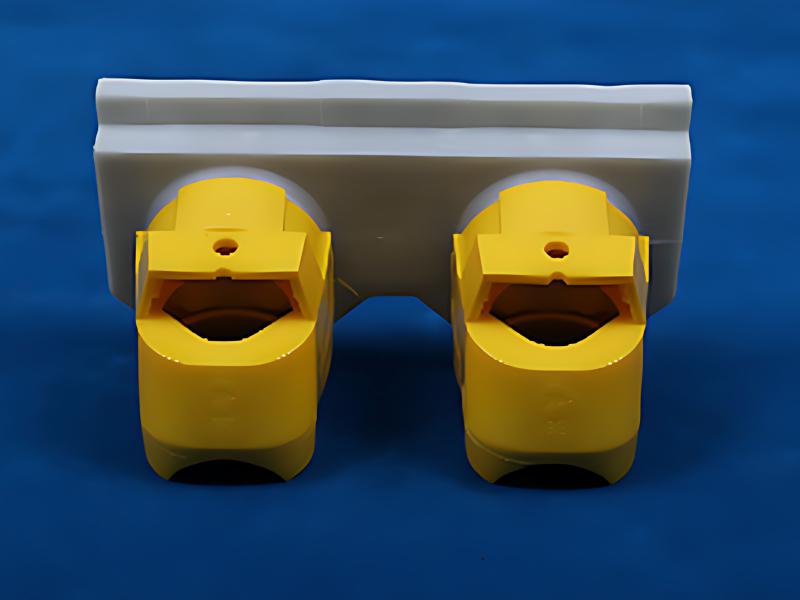

The Gripper Assembly New Type for LR Autodoffer is engineered to deliver enhanced fiber gripping and consistent performance during Autodoffer operations. Manufactured from high-strength industrial materials, it ensures durability and long service life under continuous use. The new-type design offers improved gripping accuracy and operational stability. Precision machining guarantees accurate alignment and smooth movement within Autodoffer assemblies. Its wear- and corrosion-resistant surface enhances reliability in demanding textile production environments.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Gripper Assembly New Type LR Autodoffer

- Component Type Autodoffer Gripper Assembly

- Material High-Strength Industrial Metal / Alloy

- Design New Type

- Application LR Autodoffer Spinning Machines

- Function Fiber Gripping & Doffing

Other Attributes

- Surface Finish Wear- and Corrosion-Resistant

- OEM Compatibility LR Autodoffer Machine Models

- Customization Material Grade, Dimensions, Surface Finis

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The Pallet Without Rib for LR Autodoffer is engineered to provide smooth and stable support during Autodoffer operations. Manufactured using high-strength industrial materials, it ensures durability under continuous textile production conditions. The rib-less flat design allows consistent movement and proper alignment within the Autodoffer assembly. Precision machining ensures accurate dimensions for perfect fitment. Its wear- and corrosion-resistant surface enhances long-term reliability. The pallet supports efficient mechanical movement, reducing friction and operational stress.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Pallet Without Rib LR Autodoffer Spare

- Component Type Autodoffer Pallet

- Design Without Rib / Flat Type

- Material High-Strength Industrial Metal / Alloy

- Application LR Autodoffer Spinning Machines

- Function Support & Smooth Movement

Other Attributes

- Surface Finish Wear- and Corrosion-Resistant

- OEM Compatibility LR Autodoffer Models

- Customization Material Grade, Surface Finish

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The Gripper Body for LR Autodoffer is engineered to provide strong structural support for gripper assemblies in Autodoffer systems. Manufactured from high-strength industrial materials, it ensures durability and long service life under continuous textile production. Precision machining delivers accurate dimensions for perfect alignment and fitment. The robust body design helps maintain gripper stability during high-speed doffing operations. Its wear- and corrosion-resistant surface enhances reliability in demanding mill environments. The component supports smooth movement and consistent gripping performance.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Gripper Body LR Autodoffer Component

- Component Type Autodoffer Gripper Body

- Material High-Strength Industrial Metal / Alloy

- Design Precision-Machined Body

- Application LR Autodoffer Spinning Machines

- Function Gripper Support & Housing

Other Attributes

- Surface Finish Wear- and Corrosion-Resistant

- OEM Compatibility LR Autodoffer Models

- Customization Material Grade, Dimensions, Finish

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The Spindle Brake 31.50 MM Wharve is engineered for accurate and safe spindle stopping in industrial equipment. It provides controlled braking for rotating components, ensuring reliable operation. Manufactured with durable materials for long-term use under industrial conditions. Compact design allows seamless integration into existing machinery. High precision ensures consistent performance during repeated cycles. Suitable for various mechanical and rotary systems. Ideal for industrial applications requiring dependable spindle braking and motion control.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Bore Diameter 31.50 mm

- Outer Diameter 55 mm

- Width 12 mm

- Brake Pad Thickness 3 mm

- Hub Diameter 40 mm

Other Attributes

- Hub Length 15 mm

- Weight 0.85 kg

- Maximum RPM 6000 rpm

- Operating Temperature -20°C to 150°C

- Torque Capacity 120 Nm

The Spindle Brake 24.2 MM is designed for precision control of mechanical components in industrial machinery. It offers reliable braking to halt motion accurately and safely. Manufactured with durable materials for long-lasting performance under operational stress. Compact design allows easy integration into mechanical assemblies. High precision ensures consistent performance during repeated cycles. Suitable for rotary systems, assembly lines, and precision machinery. Ideal for applications requiring dependable and controlled motion stopping.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Bore Diameter 24.2 mm

- Outer Diameter 45 mm

- Width 10 mm

- Brake Pad Thickness 2.5 mm

- Hub Diameter 32 mm

Other Attributes

- Hub Length 12 mm

- Weight 0.55 kg

- Maximum RPM 6500 rpm

- Operating Temperature -20°C to 150°C

- Torque Capacity 90 Nm

The Gear 42 Teeth is engineered for industrial power transmission applications. It enables smooth torque transfer between connected machine components. Manufactured with precision for accurate tooth alignment and consistent operational performance. Durable materials ensure long-term reliability under industrial conditions. Suitable for rotary and mechanical transmission systems. Compact design allows integration into diverse machinery assemblies. Ideal for industries requiring efficient and dependable mechanical motion control.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Teeth Count 42 Nos

- Module 2 mm

- Pitch Diameter 84 mm

- Outer Diameter 88 mm

- Bore Diameter 20 mm

- Face Width 15 mm

Other Attributes

- Hub Diameter 30 mm

- Hub Length 20 mm

- Weight 0.95 kg

- Maximum RPM 4000 rpm

- Operating Temperature -20°C to 150°C

The Bottom Peg Tapper Tip Weight 79 GM is designed for precision use in assembly operations. It ensures accurate alignment of pegs and components during mechanical assembly. Manufactured with durable material for long-term industrial use. Compact design allows easy integration into assembly tools and machines. High precision provides consistent performance across repeated operations. Suitable for various mechanical and industrial assemblies. Ideal for operations requiring controlled tapping and reliable assembly results.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Weight 79 g

- Tip Length 45 mm

- Tip Diameter 12 mm

- Shank Diameter 8 mm

- Overall Length 75 mm

Other Attributes

- Material Hardness 50 HRC

- Operating Temperature -20°C to 120°C

- Load Capacity 150 N

- Chamfer 1 mm

- Compatible Peg Size 10–12 mm