Products

The Suessen Compact Jet Insert is engineered for optimal performance in textile spinning machinery, particularly in compact spinning systems. Manufactured by Suessen, a globally recognized brand, this insert ensures uniform yarn quality and minimizes fiber breakage. Its robust design provides long-lasting durability even under high-speed spinning conditions. The insert is easy to install and maintain, reducing downtime in production. Customization options are available to meet specific machine and yarn requirements. Precision engineering guarantees smooth fiber flow and improved productivity. The insert is compatible with a variety of fiber types, enhancing versatility for different textile applications.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Brand Suessen

- Product Type Compact Jet Insert

- Material Wear-Resistant Alloy

- Compatibility Textile Spinning Machinery

- Fiber Type Compatibility Cotton, Polyester, Blends, Synthetic Fibers

- Spinning System Type Compact Spinning, Ring Spinning

- Application Yarn Production, Fiber Processing, Industrial Spinning

Other Attributes

- Customization Available on Request

- Warranty / Quality Verified Supplier, Quality-Checked

- Performance High-Precision, Durable, Energy-Efficient

- Maintenance Easy Installation and Low Maintenance

- Operational Speed High-Speed Compatible

- Efficiency Reduced Fiber Breakage, Smooth Fiber Flow

- Durability Long-Lasting Under Continuous Operation

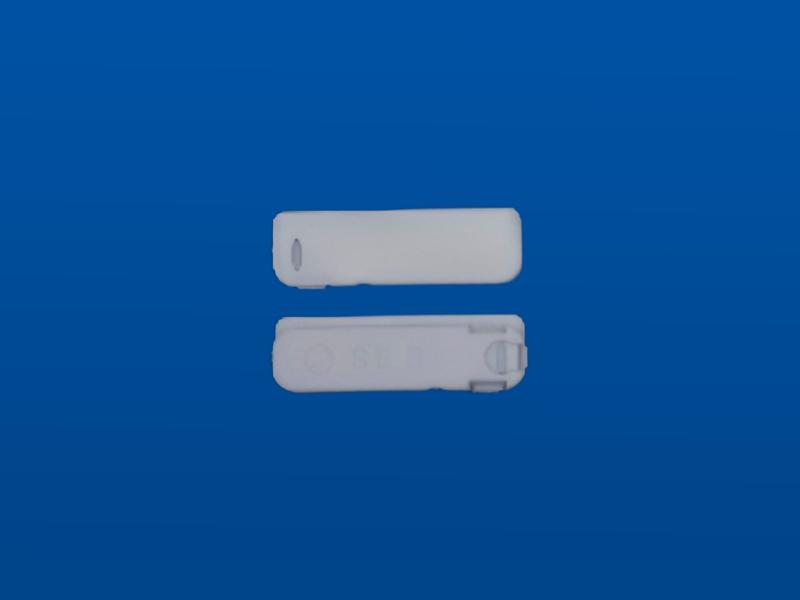

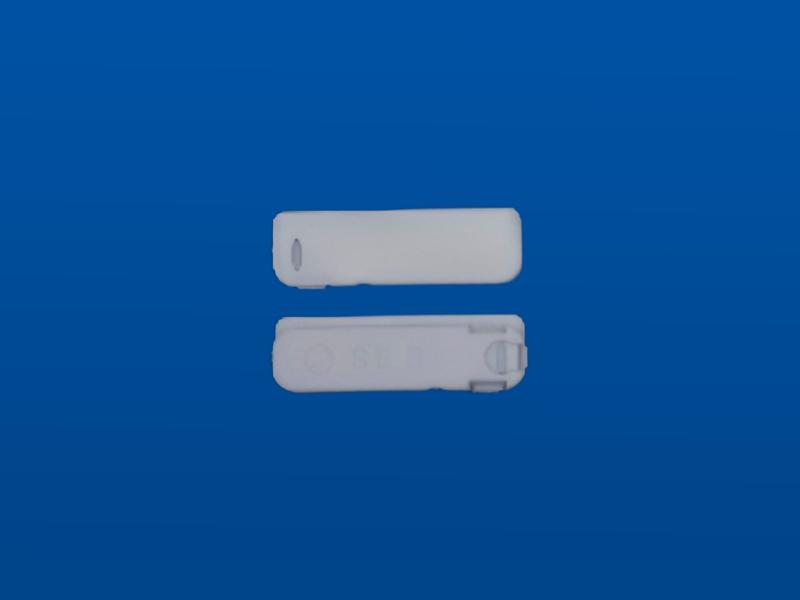

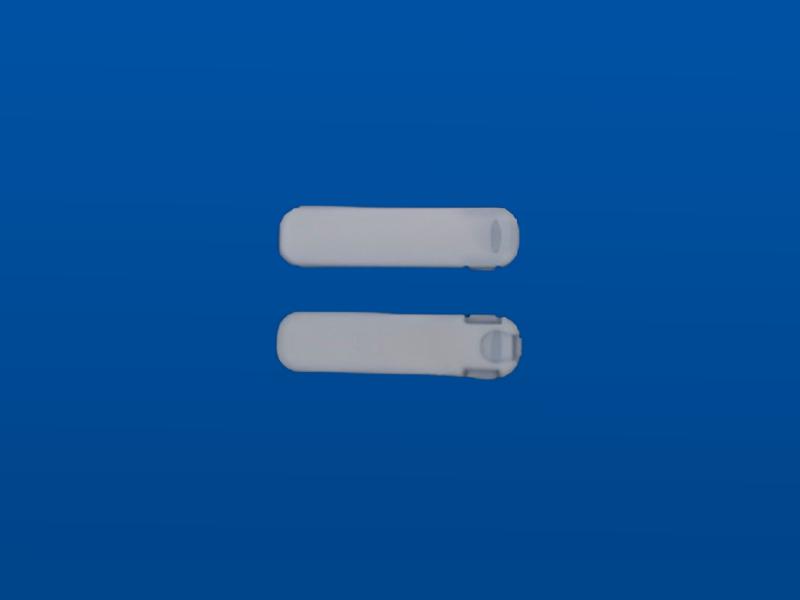

The Suessen Compact Big Insert is engineered to enhance performance in modern textile spinning equipment, ensuring smooth and consistent yarn production. Designed by Suessen, a globally recognized brand, it delivers high precision and durability for demanding industrial applications. Its robust construction minimizes fiber breakage, improving yarn quality and reducing waste. The insert is compatible with multiple fiber types, including cotton, polyester, blends, and synthetic fibers, making it highly versatile. Easy to install and maintain, it reduces downtime and simplifies operational processes in spinning mills.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Brand Suessen

- Product Type Compact Big Insert

- Material Wear-Resistant Alloy

- Compatibility Textile Spinning Equipment

- Fiber Type Compatibility Cotton, Polyester, Blends, Synthetic Fibers

- Spinning System Type Compact Spinning, Ring Spinning

- Application Yarn Production, Fiber Processing, Industrial Spinning

Other Attributes

- Customization Available on Request

- Warranty / Quality Verified Supplier, Quality-Checked

- Performance High-Precision, Durable, Energy-Efficient

- Maintenance Easy Installation and Low Maintenance

- Operational Speed High-Speed Compatible

- Efficiency Reduced Fiber Breakage, Smooth Fiber Flow

- Durability Long-Lasting Under Continuous Operation

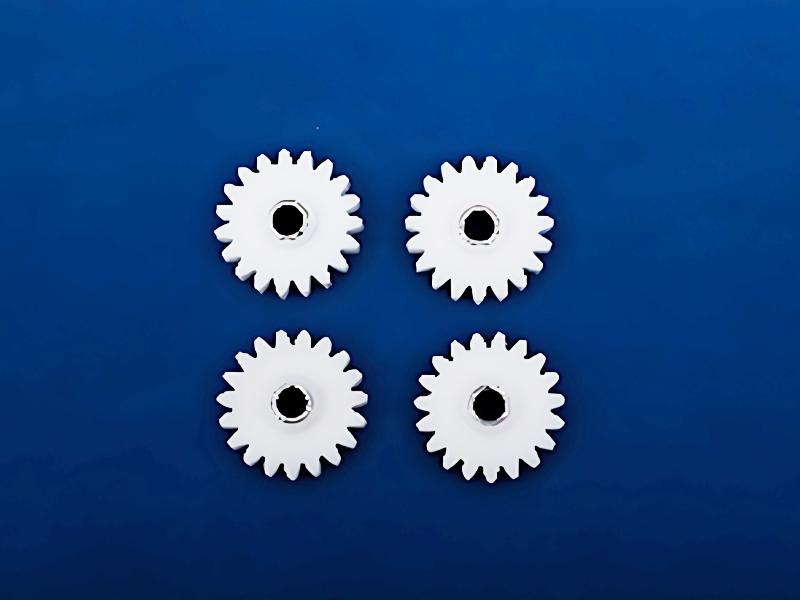

The 19 Teeth Intermediate Gear with Bush for Suessen Machines is designed to ensure efficient power transfer and consistent rotational movement in textile machinery. Engineered with precision gear teeth, it provides smooth engagement and reduced vibration during operation. The integrated bush supports proper alignment and minimizes friction, enhancing overall machine efficiency. Manufactured using high-strength materials, the gear offers excellent resistance to wear and mechanical stress. Its robust construction ensures long service life even under continuous textile production conditions.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name 19 Teeth Intermediate Gear with Bush

- Teeth Count 19 Teeth

- Component Type Intermediate Gear Assembly

- Bush Type Integrated Bush

- Material High-Strength Industrial Grade Material

- Application Suessen Textile Machines

- Function Power Transmission & Motion Control

Other Attributes

- Fitment Precision Fit for Suessen Models

- Durability High Wear Resistance

- Operation Smooth & Low-Friction Rotation

- Customization OEM & Bulk Order Customization

- Industry Textile & Spinning Machinery

- Supplier Verification Verified Machinery Spare Part Suppliers

The Cylindrical Pin for Suessen Textile Spinning Machinery is manufactured to provide precise alignment and secure positioning of mechanical parts within spinning machines. Constructed from high-strength materials, it ensures durability and long-term performance under continuous operation. The pin maintains tight tolerances, ensuring consistent fitment across assemblies. Its corrosion-resistant finish enhances longevity even in high-humidity textile environments. Designed for easy replacement and maintenance, the pin supports efficient operation of Suessen machinery. It contributes to reduced wear on surrounding components by providing stable, precise mechanical support.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Cylindrical Pin

- Component Type Precision Textile Machinery Pin

- Material High-Strength Industrial Metal

- Application Suessen Textile Spinning Machinery

- Function Alignment & Mechanical Support

- Geometry Cylindrical Shape

- Surface Finish Corrosion-Resistant

Other Attributes

- Durability Long-Term Industrial Use

- OEM Compatibility Suessen Spinning Machine Models

- Customization Size and Length Available on Request

- Maintenance Easy Installation and Replacement

- Industry Textile Manufacturing & Spinning Mill

- Supplier Verification Verified OEM and Industrial Suppliers

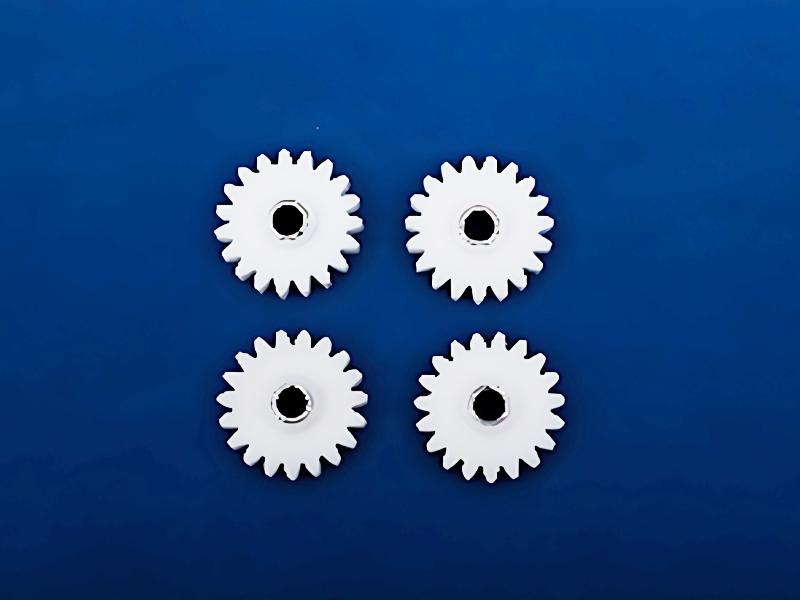

The 19 Teeth Intermediate Gear Without Bush for Suessen Machines is designed to provide efficient rotational motion and accurate power transmission in textile machinery. Manufactured with high-strength industrial materials, it ensures durability and consistent performance. The gear’s precision-cut teeth allow smooth engagement with mating gears, reducing wear and vibration. Without an integrated bush, it offers flexibility for assembly with custom bushings or machine-specific setups. Its robust construction supports continuous operation in spinning and textile processing lines.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name 19 Teeth Intermediate Gear Without Bush

- Teeth Count 19 Teeth

- Component Type Intermediate Gear Assembly

- Material High-Strength Industrial Grade Material

- Application Suessen Textile Machines

- Function Power Transmission & Motion Control

Other Attributes

- Fitment Precision Fit for Suessen Models

- Durability High Wear Resistance

- Operation Smooth, Low-Friction Rotation

- Customization OEM & Bulk Order Options

- Industry Textile & Spinning Machinery

- Supplier Verification Verified Machinery Spare Part Suppliers

The 3 Way Condenser With Screw for Suessen Spinning Machine is engineered to ensure optimal fiber condensation and mechanical stability in spinning machinery. Constructed from high-strength materials, it provides durability and long-term performance under continuous operational conditions. The integrated screw allows secure mounting and precise adjustment during installation. Its three-way design ensures even distribution of fibers and enhances spinning efficiency. Precision manufacturing ensures dimensional accuracy and reliable alignment with Suessen machine assemblies.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name 3 Way Condenser With Screw

- Component Type Condenser Assembly

- Material High-Strength Industrial Metal

- Application Suessen Spinning Machines

- Function Fiber Condensation & Mechanical Alignment

- Design Three-Way Condensation Struct

- Mounting Integrated Screw for Secure

Other Attributes

- Durability High Wear & Corrosion Resistance

- OEM Compatibility Suessen Machine Models

- Customization Size, Material, and Finish Options

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The 105 Millimetre Suction Tube for Suessen Textile Machinery is engineered to facilitate efficient fiber collection and transportation within spinning machines. Constructed from high-quality, durable materials, it ensures long-term performance under continuous operation. The tube’s precise 105 mm diameter supports optimal airflow and consistent fiber suction. Its corrosion-resistant and wear-resistant surface ensures reliability in textile production environments. The component is designed for easy integration with Suessen spinning machine assemblies, maintaining alignment and operational efficiency.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name 105 Millimetre Suction Tube

- Component Type Suction Tube Assembly

- Material High-Strength Industrial Metal / Polymer

- Diameter 105 Millimetres

- Application Suessen Textile Machinery

- Function Fiber Suction & Material Handling

Other Attributes

- Surface Finish Corrosion- and Wear-Resistant

- OEM Compatibility Suessen Spinning Machine Models

- Customization Length, Material, and Surface Options

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The 10.00 Millimetre Red Suction Nozzle for Suessen Machines is engineered to ensure efficient fiber intake and transport within spinning machinery. Constructed from high-strength materials, it provides long-lasting performance under continuous operation. The nozzle’s precise 10.00 mm diameter enables accurate suction and minimal fiber loss. Its vibrant red coating enhances visibility during assembly and maintenance. The component is designed for seamless integration with Suessen machine assemblies, maintaining alignment and optimal airflow. Precision manufacturing ensures tight tolerances and smooth surface finish, reducing operational friction.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name 10.00 Millimetre Red Suction Nozzle

- Component Type Suction Nozzle Assembly

- Material High-Strength Industrial Metal / Polymer

- Diameter 10.00 Millimetres

- Color Red

- Application Suessen Textile Machinery

- Function Fiber Suction & Collection

Other Attributes

- Surface Finish Smooth, Corrosion-Resistant

- OEM Compatibility Suessen Spinning Machine Models

- Customization Material, Diameter, and Color Options

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The 8.50 Millimetre Black Suction Nozzle for Suessen Machinery is engineered to facilitate precise fiber intake and transport within spinning machines. Manufactured from high-strength industrial materials, it provides durability and long-term performance under continuous operation. The nozzle’s exact 8.50 mm diameter ensures accurate fiber suction and minimizes material loss. Its black coating enhances visibility and helps distinguish it during assembly and maintenance tasks. Designed for seamless integration, the nozzle maintains optimal alignment and airflow in Suessen machine assemblies.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name 8.50 Millimetre Black Suction Nozzle

- Component Type Suction Nozzle Assembly

- Material High-Strength Industrial Metal / Polyme

- Diameter 8.50 Millimetres

- Color Black

- Application Suessen Textile Machinery

- Function Fiber Suction & Collection

Other Attributes

- Surface Finish Smooth, Corrosion-Resistant

- OEM Compatibility Suessen Spinning Machine Models

- Customization Material, Diameter, and Color Options

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The 6.3 Millimetre Red Suction Nozzle for Textile Spinning Use is engineered to provide precise fiber intake and smooth transport within spinning machines. Manufactured from high-strength industrial materials, it ensures long-term performance under continuous operation. Its 6.3 mm diameter allows accurate suction while minimizing fiber loss. The vibrant red coating enhances visibility during assembly, maintenance, and quality checks. Designed for seamless integration, the nozzle maintains optimal alignment and airflow in spinning equipment. Precision manufacturing ensures smooth surface finish and tight tolerances, reducing friction and operational wear.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name 6.3 Millimetre Red Suction Nozzle

- Component Type Suction Nozzle Assembly

- Material High-Strength Industrial Metal / Polymer

- Diameter 6.3 Millimetres

- Color Red

- Application Textile Spinning Machinery

- Function Fiber Suction & Collection

Other Attributes

- Surface Finish Smooth, Corrosion-Resistant

- OEM Compatibility Spinning Machine Models

- Customization Material, Diameter, and Color Options

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The 5.8 Millimetre Black Suction Nozzle for Suessen Machines is engineered to ensure precise fiber intake and smooth transport in spinning machinery. Manufactured from high-strength industrial materials, it provides durability and reliable performance under continuous operation. The 5.8 mm diameter allows accurate suction with minimal fiber loss. Its black coating improves visibility during installation and maintenance. Designed for seamless integration, the nozzle maintains optimal alignment and airflow in Suessen machine assemblies. Precision manufacturing guarantees smooth surface finish and tight tolerances, reducing friction and wear.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name 5.8 Millimetre Black Suction Nozzle

- Component Type Suction Nozzle Assembly

- Material High-Strength Industrial Metal / Polymer

- Diameter 5.8 Millimetres

- Color Black

- Application Suessen Textile Machinery

- Function Fiber Suction & Collection

Other Attributes

- Surface Finish Smooth, Corrosion-Resistant

- OEM Compatibility Suessen Spinning Machine Models

- Customization Material, Diameter, and Color Options

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The 17 T Top Roller 100 Millimetre for Suessen Spinning is engineered to ensure precise fiber drafting and uniform top card operation in spinning machines. Constructed from high-strength materials, it delivers long-term durability and reliable performance under continuous operation. The 100 mm diameter provides optimal contact with fibers, enhancing drafting efficiency and minimizing fiber breakage. Its precision-machined surface ensures smooth rotation and reduced friction during high-speed spinning. Designed for seamless integration, the roller aligns perfectly with Suessen spinning machine assemblies. The component resists wear and corrosion, ensuring extended service life in textile production environments.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name 17 T Top Roller 100 Millimetre

- Component Type Top Roller Assembly

- Material High-Strength Industrial Metal / Alloy

- Diameter 100 Millimetres

- Teeth Count 17 T

- Application Suessen Spinning Machinery

- Function Fiber Drafting & Top Card Operation

Other Attributes

- Surface Finish Precision Machined, Wear-Resistant

- OEM Compatibility Suessen Spinning Machine Models

- Customization Material, Diameter, and Surface Finish Options

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The 22 T Top Roller 100 Millimetre for Suessen Machinery is engineered to provide precise fiber drafting and uniform operation in spinning machines. Manufactured from high-strength materials, it delivers long-term durability and reliable performance under continuous operation. The 100 mm diameter ensures optimal fiber contact, improving drafting efficiency and minimizing fiber breakage. Its precision-machined surface allows smooth rotation and reduces friction during high-speed spinning. The roller is designed for seamless integration with Suessen machine assemblies, maintaining alignment and consistent operation.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name 22 T Top Roller 100 Millimetre

- Component Type Top Roller Assembly

- Material High-Strength Industrial Metal / Alloy

- Diameter 100 Millimetres

- Teeth Count 22 T

- Application Suessen Spinning Machinery

- Function Fiber Drafting & Top Card Operation

Other Attributes

- Surface Finish Precision Machined, Wear-Resistant

- OEM Compatibility Suessen Spinning Machine Models

- Customization Material, Diameter, and Surface Finish Options

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The Elitop Assembly Without Cots for Suessen Compact Spinning is engineered to ensure reliable fiber handling and consistent spinning performance. Manufactured from high-strength industrial materials, it provides durability and long-term operation under continuous use. The assembly is designed without cots, allowing flexible integration with specific machine configurations. Precision engineering guarantees accurate alignment and smooth operation within Suessen compact spinning units. Its wear- and corrosion-resistant construction ensures longevity in demanding textile production environments. Easy installation and maintenance minimize downtime and improve operational efficiency.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Elitop Assembly Without Cot

- Component Type Compact Spinning Assembly

- Material High-Strength Industrial Metal / Alloy

- Application Suessen Compact Spinning Machines

- Function Fiber Handling & Spinning Performance

- Design Assembly Without Cots

Other Attributes

- Surface Finish Wear- and Corrosion-Resistant

- OEM Compatibility Suessen Compact Spinning Models

- Customization Material, Dimensions, Assembly Configuration

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The Elitop Assembly Without Cots New Type for Suessen Machine is engineered to provide enhanced fiber handling and consistent performance in spinning operations. Manufactured from high-strength industrial materials, it ensures long-term durability and reliable function under continuous use. The new-type design without cots allows flexible integration with various Suessen machine configurations. Precision engineering guarantees accurate alignment, smooth operation, and minimal mechanical wear. Its corrosion- and wear-resistant construction ensures extended service life in demanding textile production environments.

Cash,Cheque

Key Attributes

Industry-specific Attributes

- Product Name Elitop Assembly Without Cots New Type

- Component Type Spinning Machine Assembly

- Material High-Strength Industrial Metal / Alloy

- Application Suessen Spinning Machines

- Function Fiber Handling & Spinning Performance

- Design New Type Without Cots

Other Attributes

- Surface Finish Wear- and Corrosion-Resistant

- OEM Compatibility Suessen Machine Models

- Customization Material, Dimensions, Assembly Configuration

- Maintenance Easy Installation & Replacement

- Industry Textile & Spinning Machinery

- Supplier Verification Verified OEM & Industrial Suppliers

The Eltrox Enclosure Box is designed to securely house electrical assemblies and control components. Its new design supports organized wiring and easy maintenance access. Built with durable materials, it offers reliable protection in industrial conditions. Suitable for panel boards, switches, and electrical modules. Ventilation and layout ensure safe heat dissipation. Compact structure allows convenient installation in various setups. Ideal for industrial and commercial electrical applications.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Height 300 mm

- Width 250 mm

- Depth 120 mm

- Thickness 1.2 mm

- Weight 2.8 kg

- IP Rating IP65

- Mounting Holes 4 Nos

Other Attributes

- Door Opening Angle 120°

- Lock Points 2 Nos

- Cable Entry Slots 6 Nos

- Operating Temperature -20°C to 55°C

- Powder Coating Thickness 80 microns

- Load Capacity 15 kg

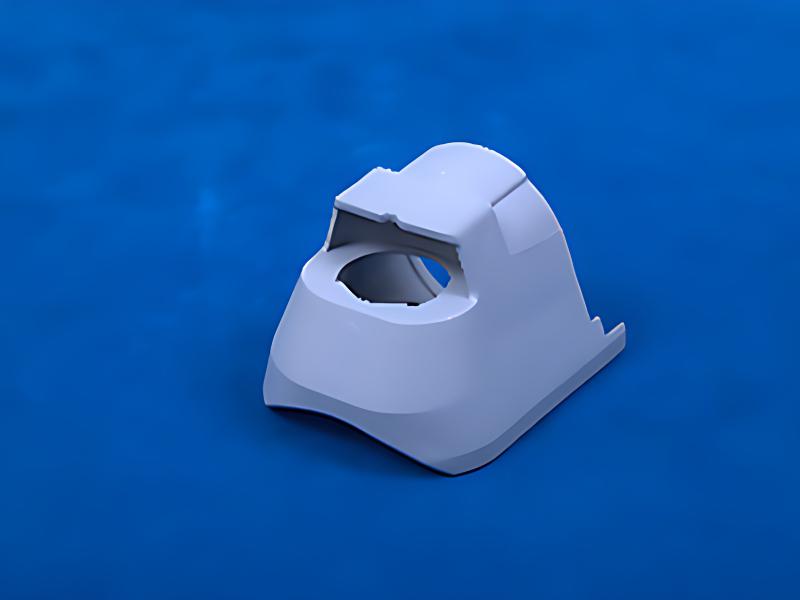

The SCL Plus Insert Component is designed for secure and accurate machine fittings in industrial assemblies. It ensures proper alignment and stability of connected parts during operation. Manufactured with precision for consistent performance under working conditions. Suitable for various machine structures and fitting requirements. Durable material supports long-term usage with minimal wear. Compact design allows easy integration into assemblies. Ideal for machinery requiring strong, stable, and precise fitting support.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Length 60 mm

- Outer Diameter 18 mm

- Inner Diameter 10 mm

- Thread Size M10

- Thread Pitch 1.5 mm

- Head Diameter 24 mm

- Head Thickness 4 mm

Other Attributes

- Insert Depth 35 mm

- Material Hardness 45 HRC

- Weight 0.12 kg

- Tolerance ±0.02 mm

- Load Capacity 2.5 kN

- Operating Temperature -10°C to 120°C

Shaft C Plain Rod is designed for efficient mechanical rotation in industrial systems. It enables smooth motion transfer between connected machine components. Manufactured with precision for alignment accuracy and stable performance. Suitable for rotary mechanisms and transmission setups. Durable construction ensures long-term reliability under working conditions. Simple cylindrical design allows easy installation and maintenance. Ideal for machinery requiring consistent and controlled rotational movement.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Length 750 mm

- Diameter 30 mm

- Straightness Tolerance 0.04 mm

- Surface Finish 1.0 µm

- Hardness 42 HRC

Other Attributes

- Weight 4.2 kg

- Roundness Tolerance 0.03 mm

- Load Capacity 8 kN

- Operating Temperature -20°C to 160°C

- End Chamfer 2.5 mm

The Shaft A Solid Bar is designed for industrial equipment assembly requiring strength and precision. It supports stable motion transfer between connected machine components. Manufactured with high-quality material for durability under working conditions. Precision finish ensures accurate alignment in mechanical systems. Solid construction resists stress and operational loads. Easy integration allows use across multiple machinery designs. Ideal for equipment demanding dependable and consistent shaft performance.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Length 600 mm

- Diameter 28 mm

- Straightness Tolerance 0.03 mm

- Surface Finish 0.9 µm

- Hardness 41 HRC

Other Attributes

- Weight 2.9 kg

- Roundness Tolerance 0.02 mm

- Load Capacity 6 kN

- Operating Temperature -20°C to 150°C

- End Chamfer 2 mm

Shaft B Support Rod is designed to provide dependable support in machinery transmission systems. It assists in maintaining alignment between rotating components during operation. Manufactured with precision for stable and consistent performance. Suitable for various transmission and rotary assemblies. Durable construction withstands operational stress and wear. Simple design allows easy installation and integration. Ideal for machinery requiring steady support and accurate motion transfer.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Length 680 mm

- Diameter 26 mm

- Straightness Tolerance 0.03 mm

- Surface Finish 0.9 µm

- Hardness 40 HRC

Other Attributes

- Weight 3.3 kg

- Roundness Tolerance 0.02 mm

- Load Capacity 6.5 kN

- Operating Temperature -20°C to 150°C

- End Chamfer 2 mm

Shaft D Drive Rod is engineered for effective motion transfer in mechanical systems. It supports stable rotation between connected machine components. Manufactured with precision for accurate alignment and smooth performance. Suitable for transmission and rotary motion assemblies. Durable construction withstands operational stress and continuous usage. Simple cylindrical design allows easy installation and maintenance. Ideal for machinery requiring dependable drive and motion support.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Length 820 mm

- Diameter 32 mm

- Straightness Tolerance 0.04 mm

- Surface Finish 1.0 µm

- Hardness 43 HRC

Other Attributes

- Weight 5.1 kg

- Roundness Tolerance 0.03 mm

- Load Capacity 9 kN

- Operating Temperature -20°C to 160°C

- End Chamfer 3 mm

Dual Type Drive Shaft is designed for efficient power transmission in mechanical systems. It supports synchronized rotation between connected components. Precision manufacturing ensures accurate alignment and smooth motion. Suitable for rotary and transmission assemblies in industrial machinery. Strong construction withstands continuous operational load. Simple design allows easy installation and servicing. Ideal for systems requiring dependable power and motion transfer.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Total Length 900 mm

- Primary Diameter 35 mm

- Secondary Diameter 28 mm

- Step Length 120 mm

- Straightness Tolerance 0.05 mm

- Surface Finish 1.2 µm

Other Attributes

- Hardness 45 HRC

- Roundness Tolerance 0.03 mm

- Weight 6.8 kg

- Load Capacity 12 kN

- Operating Temperature -20°C to 170°C

- End Chamfer 3 mm

Intermediate Shaft 302 MM is designed for effective motion transfer in mechanical equipment. It connects components to maintain synchronized rotation. Precision machining ensures accurate alignment and smooth performance. Suitable for transmission and rotary motion assemblies. Durable build withstands operational stress and long usage cycles. Straight design allows easy installation and maintenance. Ideal for systems requiring consistent motion support.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Length 302 mm

- Diameter 22 mm

- Straightness Tolerance 0.03 mm

- Surface Finish 0.8 µm

- Hardness 40 HRC

Other Attributes

- Weight 0.95 kg

- Roundness Tolerance 0.02 mm

- Load Capacity 4.5 kN

- Operating Temperature -20°C to 150°C

- End Chamfer 2 mm

Intermediate Shaft 308 MM is engineered for efficient motion transmission in mechanical systems. It links components to maintain synchronized rotation. Precision machining ensures accurate alignment and smooth performance. Suitable for rotary and transmission assemblies in machinery. Strong construction withstands continuous operational load. Straight design allows easy installation and servicing. Ideal for systems requiring dependable motion transfer.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Length 308 mm

- Diameter 24 mm

- Straightness Tolerance 0.03 mm

- Surface Finish 0.8 µm

- Hardness 41 HRC

Other Attributes

- Weight 1.15 kg

- Roundness Tolerance 0.02 mm

- Load Capacity 5 kN

- Operating Temperature -20°C to 150°C

- End Chamfer 2 mm

Timing Pulley 36 Teeth is designed for precise synchronized belt movement in mechanical systems. It ensures accurate motion transfer without slippage. Precision tooth profile supports consistent belt engagement. Suitable for power transmission and rotary assemblies. Durable construction withstands operational stress and wear. Compact design allows easy installation and alignment. Ideal for machinery requiring dependable timing and motion control.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Teeth Count 36 Nos

- Outer Diameter 58 mm

- Bore Diameter 12 mm

- Face Width 25 mm

- Pitch 5 mm

- Keyway Width 4 mm

Other Attributes

- Hub Diameter 32 mm

- Hub Length 18 mm

- Weight 0.45 kg

- Maximum RPM 4500 rpm

- Operating Temperature -10°C to 120°C

Timing Pulley 41 Teeth is engineered for precise synchronized belt movement in mechanical systems. It delivers accurate motion transfer with minimal slippage. Precision tooth profile ensures consistent belt engagement. Suitable for timing and power transmission assemblies. Strong construction withstands operational stress and wear. Compact design allows easy installation and alignment. Ideal for machinery requiring dependable motion control and timing accuracy.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Teeth Count 41 Nos

- Outer Diameter 66 mm

- Bore Diameter 14 mm

- Face Width 28 mm

- Pitch 5 mm

- Keyway Width 5 mm

Other Attributes

- Hub Diameter 36 mm

- Hub Length 20 mm

- Weight 0.62 kg

- Maximum RPM 4200 rpm

- Operating Temperature -10°C to 120°C

Idler Gear 15 Teeth is designed to maintain alignment and tension in mechanical systems. It supports smooth motion flow between connected components. Precision tooth profile ensures consistent engagement and stability. Suitable for timing and transmission assemblies. Durable construction withstands operational stress and wear. Compact design allows easy installation and adjustment. Ideal for machinery requiring stable alignment and controlled tension.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Teeth Count 15 Nos

- Module 2 mm

- Pitch Diameter 30 mm

- Outer Diameter 34 mm

- Bore Diameter 10 mm

- Face Width 12 mm

Other Attributes

- Hub Diameter 26 mm

- Hub Length 14 mm

- Weight 0.28 kg

- Maximum RPM 5000 rpm

- Operating Temperature -10°C to 120°C

Mango Tube Grommet is designed to protect cables and pipes in mechanical setups. It prevents abrasion where lines pass through panels or frames. Flexible material ensures a snug and secure fit. Suitable for wire routing and pipe passage applications. Durable construction withstands environmental and operational stress. Simple design allows quick installation and replacement. Ideal for systems requiring safe cable and pipe management.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Outer Diameter 32 mm

- Inner Diameter 20 mm

- Groove Diameter 26 mm

- Groove Width 3 mm

- Flange Diameter 38 mm

Other Attributes

- Thickness 4 mm

- Weight 0.03 kg

- Hardness 65 Shore A

- Operating Temperature -20°C to 90°C

- Cable Capacity 18 mm

Suction Tube 1C is engineered for efficient fluid and material transfer. The integrated nozzle ensures precise suction and discharge. Secure clip maintains stable attachment during operation. Flexible and durable material supports long-term use. Suitable for industrial, mechanical, and processing equipment. Compact design allows easy installation and handling. Ideal for systems requiring dependable suction and leak-free performance.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Tube Length 1200 mm

- Outer Diameter 25 mm

- Inner Diameter 18 mm

- Nozzle Diameter 12 mm

- Clip Width 15 mm

Other Attributes

- Tube Thickness 3 mm

- Weight 0.45 kg

- Material Hardness 60 Shore A

- Operating Temperature -10°C to 80°C

- Maximum Suction Pressure 0.8 bar

Suction Tube Grommet is designed to protect pipes and tubes where they pass through panels or openings. Flexible and durable material prevents wear and abrasion. Ensures secure and stable placement of suction tubes. Suitable for industrial, mechanical, and processing equipment. Simple design allows easy installation and replacement. Withstands operational stress and environmental conditions. Ideal for systems requiring safe and reliable pipe entry protection.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Outer Diameter 40 mm

- Inner Diameter 25 mm

- Groove Diameter 30 mm

- Groove Width 4 mm

- Flange Diameter 48 mm

Other Attributes

- Thickness 5 mm

- Weight 0.05 kg

- Hardness 65 Shore A

- Operating Temperature -20°C to 90°C

- Pipe Capacity 25 mm

Adjustable Spacers 25–40 MM are designed for accurate alignment in mechanical assemblies. The adjustable range allows customization between 25 and 40 MM. Durable material ensures long-term use under operational stress. Suitable for industrial machinery and equipment setups. Compact design allows easy installation and removal. Maintains consistent spacing and supports component stability. Ideal for systems requiring precise mechanical alignment.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Minimum Length 25 mm

- Maximum Length 40 mm

- Outer Diameter 18 mm

- Inner Diameter 10 mm

- Thread Size M10

Other Attributes

- Weight 0.06 kg

- Material Hardness 45 HRC

- Operating Temperature -20°C to 120°C

- Adjustment Range 15 mm

- Load Capacity 2.5 kN

Pin Spacer 40 MM Groove is engineered for precise alignment and secure assembly of mechanical components. The grooved design ensures stable positioning during operation. Durable construction withstands operational stress and repeated use. Suitable for industrial machinery and equipment assemblies. Compact design allows easy installation and removal. Maintains consistent spacing for accurate mechanical function. Ideal for systems requiring dependable alignment and assembly stability.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Length 40 mm

- Outer Diameter 12 mm

- Inner Diameter 6 mm

- Groove Width 2 mm

- Groove Depth 1.5 mm

Other Attributes

- Weight 0.02 kg

- Material Hardness 42 HRC

- Operating Temperature -20°C to 120°C

- Load Capacity 1.5 kN

- Chamfer 1 mm

End Plug L Airy is designed for sealing multi-color components in industrial assemblies. Its precise fit ensures secure placement and protection against dust and contaminants. Manufactured for durability and consistent performance under operational conditions. Suitable for various machinery and assembly lines requiring color-coded or multi-part sealing. Lightweight airy design simplifies installation and handling. Resistant to wear and compatible with industrial-grade materials. Ideal for equipment requiring reliable, visually coded component sealing.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Length 28 mm

- Outer Diameter 15 mm

- Inner Diameter 10 mm

- Flange Diameter 20 mm

- Flange Thickness 2 mm

Other Attributes

- Weight 0.01 kg

- Material Hardness 60 Shore A

- Operating Temperature -20°C to 90°C

- Seal Depth 5 mm

- Compatible Component Diameter 10–12 mm

The Lattice Apron Yellow Five Meter is designed for industrial protection and safety in workshops and factories. Its durable lattice construction offers robust coverage while allowing airflow and visibility. The bright yellow color ensures high visibility for safety compliance. Ideal for covering machinery, workstations, or hazardous areas to prevent accidents. Lightweight design allows easy installation and handling. Resistant to wear and industrial conditions for long-term use. Perfect for environments requiring both protection and operational visibility.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Length 5000 mm

- Width 1200 mm

- Mesh Size 10 mm × 10 mm

- Thickness 1.5 mm

- Weight 2.8 kg

Other Attributes

- Material Tensile Strength 35 MPa

- Color Yellow

- Operating Temperature -20°C to 80°C

- UV Resistance Yes, up to 1000 hours

- Edge Reinforcement Width 25 mm

The Half Gear Box Unit is engineered for reliable mechanical power transmission in industrial machinery. It ensures smooth transfer of torque between connected shafts and components. Manufactured with precision for accurate gear alignment and consistent performance. Durable materials provide long-term operational reliability under load conditions. Compact design allows integration into various machine assemblies. Designed for easy maintenance and inspection. Ideal for industrial equipment requiring stable and efficient mechanical power transmission.

Cheque,NEFT

Key Attributes

Industry-specific Attributes

- Input Shaft Diameter 25 mm

- Output Shaft Diameter 30 mm

- Gear Ratio 01:03

- Housing Length 180 mm

- Housing Width 120 mm

Other Attributes

- Housing Height 140 mm

- Weight 7.5 kg

- Max Torque Capacity 150 Nm

- Operating Temperature -20°C to 120°C

- Mounting Hole Diameter 8 mm (4 Nos)